Journal Name: Scholar Journal of Applied Sciences and Research

Article Type: Research

Received date: 18 June, 2019

Accepted date: 25 June, 2019

Published date: 30 June, 2019

Citation: Ngoc Huy DT (2019) Applications and Advantages of Rcarbon Black; A Business Model in Developing Countries. Sch J Appl Sci Res Vol: 2, Issu: 8 (26-30).

Copyright: © 2019 Ngoc Huy DT. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

The global issue of waste tires in particular and industrial solid waste has been becoming an environmental problem in developing countries such as Vietnam and moreover, it is a global problem needed to be thoroughly resolved. According to statistics, Viet Nam discharges about 400,000 tons of waste tires annually and this number in the US is estimated about 4,200,000 tons per year. This creates many environmental issues. Hence, this paper aims to propose a business model to solve problems mentioned below in the paper. Taking advantage of pyrolysis technology is one method to convert wastes into clean energy such as r-carbon black (recovered carbon) and protecting our environment. This is one main objective of this research paper. Analysis of applications of carbon black (finished product) is the 2nd goal of this research paper. Through the economic and technical analysis of this model, we can see the practical benefits of the energy project in terms of economic efficiency, profitability, which bring surplus value for investors, effective solutions for customers and a quality energy product for the society. And it also suggests the relevant goverrment of developing countries to consider proper policies to encourage environment protection and businesses in the field of converting industrial wastes such as tires into clean energy.

Exposure to gaming, for example, has proven conducive for learning real-world abilities through auditory and visual stimuli. We will discuss cortical magnification and receptive field sizes, as well as topographic brain maps in the context of neuroplasticity. We finally propose more studies to be performed to improve musical talent and musical abilities.

JEl: L23, L65, M11

Keywords: Pyrolysis, Shredder, Clean energy, Carbon black.

Abstract

The global issue of waste tires in particular and industrial solid waste has been becoming an environmental problem in developing countries such as Vietnam and moreover, it is a global problem needed to be thoroughly resolved. According to statistics, Viet Nam discharges about 400,000 tons of waste tires annually and this number in the US is estimated about 4,200,000 tons per year. This creates many environmental issues. Hence, this paper aims to propose a business model to solve problems mentioned below in the paper. Taking advantage of pyrolysis technology is one method to convert wastes into clean energy such as r-carbon black (recovered carbon) and protecting our environment. This is one main objective of this research paper. Analysis of applications of carbon black (finished product) is the 2nd goal of this research paper. Through the economic and technical analysis of this model, we can see the practical benefits of the energy project in terms of economic efficiency, profitability, which bring surplus value for investors, effective solutions for customers and a quality energy product for the society. And it also suggests the relevant goverrment of developing countries to consider proper policies to encourage environment protection and businesses in the field of converting industrial wastes such as tires into clean energy.

Exposure to gaming, for example, has proven conducive for learning real-world abilities through auditory and visual stimuli. We will discuss cortical magnification and receptive field sizes, as well as topographic brain maps in the context of neuroplasticity. We finally propose more studies to be performed to improve musical talent and musical abilities.

JEl: L23, L65, M11

Keywords: Pyrolysis, Shredder, Clean energy, Carbon black.

Introduction

Annually, Vietnam and other countries around the world release about 14 million tons of waste tires, which presents one of the global serious issues of solid waste. Recycling industrial wastes has been recognized as one of ways to reduce adverse impact of global warming and negative effect of greenhouse gases. According to statistics, Viet Nam discharges about 400,000 tons of waste tires annually and this number in the US is estimated about 4,200,000 tons per year (Table 1) [1].

Several environmental impacts of used tires are: Huge quantities of scrap tires are the living source of flies, mosquitoes, cockroaches, disease-causing parasites, and fever viruses. Besides, Potential fire hazard from waste tires will cause acid smoke that is harmful to the environment and human health. Scrap tires also take up landfill space and are dirty while the precious natural resource has been becoming scarce (Figure 1).

Recycling and converting waste tires into clean energy is becoming a crucial method to reduce bad effects of global warming and greenhouse gases.

Research Issues

This paper will find out:

Research issue 1: what is the business model to convert industrial wastes such as waste tires into clean energy such as carbon black in developing countries?

Research issue 2: what are solutions that developed countries can help and provide developing countries in this field?

Research issue 3: what are applications and advantages of carbon black as finished product?

| Country | The number of waste tires annually (tons) |

|---|---|

| US | 4,200,000 |

| Europe | 3,400,000 |

| Japan | 1,000,000 |

| Viet Nam | 400,000 |

| Others | 5,200,000 |

Table 1: Country wise analysis of waste tires discharge [1].

Figure 1: Environmental impacts of used tires.

Previous Studies

Waste tires pyrolysis is well known method for thermal recycling by heating at near 500°C with purpose of liquid oil and carbon black by-production as near 50% and 35% yield correspondingly, including about 10% combustible off-gas residual after oil condensing and 5% wire steel cord in rest (all relatively to tire mass) [2].

Then, Rani S and Agnihotri R [3] also indicated recycling of scrap tyre pyrolysis gives comparable efficiency to diesel oil in medium to high load but it has been question on the desulfurization process. More improvement in fuel quality in term of desulfurization, reduction in viscosity is required for tyre oil as an alternate fuel for diesel engine.

Elshokary et al. [4] provided a lot of data about the pyrolysis of waste tires with respect to the type of reactors used associated with the experimental conditions (temperature, heating rate, type of catalyst) and its effects on the products of pyrolysis.

Finally, Han et al. [5] mentioned that according to MS and Thermogravimetric (TG) curves, tyre pyrolysis could be divided into four stages. The first stage was due to water vaporization and plasticizer decomposition at the temperature below 320°C. The secondary stage was attributed to natural rubber decomposition at 320–400°C, and the third stage was related to the decomposition of synthetic rubber, which took place at 400–520°C. The fourth stage was occurred above 520°C.

Finding on a Business Model in Developing Countries

(Input) Raw materials: Industrial wastes: plastic or waste tires

According to statistics, Viet Nam discharges about 400,000 tons of waste tires annually and this number in the US is estimated about 4,200,000 tons per year [1].

Global car sales continue to rise in the first half of 2018, data provided by JATO, an auto market research firm, show in 57 countries worldwide, total revenue of car industry in the world in the first half of 2018 reached 44 million cars, increase 3.6% compared to the same period in 2017 (Figure 2) [6].

Viet Nam’s vehicle consumption growth forecasted will reach 22.6% per annum during 2018-2025 and reach 18.5% per annum during the period 2025-2035.

It is forecasted that by 2020, the demand for the domestic automobile market will be about 500,000-600,000 cars and the automobile market will be driven by the GDP per capita surpassing 3,000 USD and the average ownership will be about more than 50 vehicles / 1,000 people. The trend will also take place in Viet Nam during the period 2020-2030.

Thus, the automotive market is expected to reach 750,000-800,000 cars by 2025 and reach 1,7-1,85 million cars by 2035 [7].

With the number of cars currently in reality and the growth forecasted as above, the number of waste automobile tires are very large, ensuring the input materials for the plant.

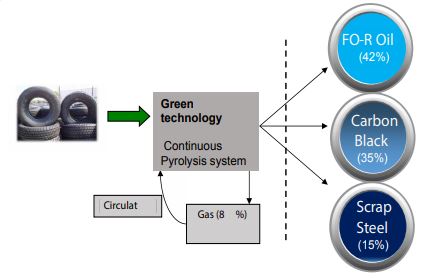

Process (pyrolysis system) is shown in Figure 3 [8].

| Product name | Application |

|---|---|

| FO-R oil from rubber, waste tire (42%) | Fuel oil for steam boiler and dry kiln, production of glass, steel and ceramic tile, replacing FO oil. If additional distillation is used, we can obtain products (petrol, diesel, asphalt). |

| Carbon black (35%) | Used as a solid fuel, replacing activated carbon as a filler in the processing of rubber products, paint pigments, cement, wire casing. |

| Gas (Hydrocacbon) (8%) | Circulated, fully utilized for heating at the pyrolysis equipment, saving energy for the project; |

| Scrap steel (15%) | High quality steel components, used as raw materials for making steel billet. |

Table 2: Product catalog and application.

Figure 2: Global car sales continue to rise in the first half of 2018, data provided by JATO, an auto market research firm, show in 57 countries worldwide, total revenue of car industry in the world in the first half of 2018 reached 44 million cars, increase 3.6% compared to the same period in 2017 [6].

Figure 3: Process (pyrolysis system).

Advantages

The advantage of the continuous pyrolysis line is that it separates steel from the beginning by cutting and filtering rubber to increase the quality and price of scrap steel compared to the current line system. The second advantage is that the new line system uses automatic coal packing system to reduce the environmental pollution caused by coal dust compared to the current method. A third advantage is the cost savings made by the continuous pyrolysis line which is automatically controlled and does not process water during pyrolysis.

Shredder suppliers in the US such as Ecogreen can provide energy companies with shredding system which help to cut the whole tires into small pieces (with diamers less than 25 mm). Then, they can be put into pyrolysis system and be converted into finished products with roper pyrolysis yield. Therefore, we can build a shredding tire plant in California to cut the whole tires into shreded tires then we export to developing countries like Vietnam to convert into clean energy through pyrolysis system [9,10].

(Output) Finished products: FO-R oil, carbon black, scrap steel

The product mix of the project is applied in the areas shown in Table 2.

Advantages of carbon black (finished products):

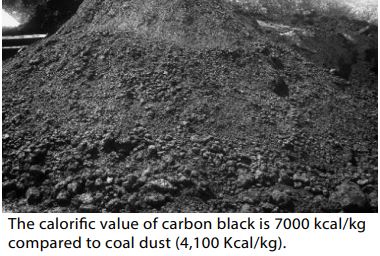

Carbon black recovered (rCB) through pyrolysis has more environmental benefits than traditional pure carbon black. Specifically:

- Unlike coal dust, rCB production does not lead to significant emissions of sulfur oxides and nitrogen oxides (SOx / NOx) or particles.

- Each ton of carbon black recovered (rCB) saves about 2.5 tons of carbon dioxide compared to the traditional carbon black production method.

In addition to environmental benefits, rCB has other benefits such as: rCB can be made into pills like pure black coal - granulating increases the density of coal dust so it is easy to transport and store, handle and mix [11].

The coal consumption demand in Viet Nam has been increasing over 10 years (2006-2017) as shown in Figure 4.

Coal consumption in Viet Nam:

The increasing demand for coal is also shown in the Figure 5, in 2017, it is 28.2 MTOE (i.e. 19.7 million tons), an increase of 392%, 5 times higher than 2006.

Figure 4: The calorific value of carbon black.

Figure 5: The calorific value of carbon black.

Conceptual Theories

The increasing demand for energy production and dealing with larger amounts of waste pushes renewable energy companies to solve the produced pollutant waste, emit lesser amounts of CO2, and generate more energy. Recycling of scrap tires become one of perfect solutions for the recent requirements of the 21st century.

In the context of the depletion of natural resources, the quality of the environment seriously affected by the pace of development of industries and urbanization, the reuse and recycling of industrial wastes into production is necessary, because two (2) reasons: in addition to reducing the burden of environmental pollution and protecting the resources of future generations, it also helps businesses save a large amount of money in production and lower production cost (the cost of buying FO-R oil from used rubber is much lower than that of other natural fuels).

Limitation of the Model

Firstly, some countries do not widely notice their supporting policies in the field of pyrolysis of industrial wastes into clean energy. Secondly, finding a good source of capital for businesses in this field is still limited and difficult. Finally, we need to find a proper mechanism for developed countries to transfer their resources to developing countries.

Discussion for Further Research

Regarding the pyrolysis technology, developing countries still need to figure out the optimized solution to produce good finished outputs and to increase profits.

Conclusion and Policy Suggestion

A global issue: 14 million tons of end-of-life tires are accumulated annuallly in theo world and are today one of the worst global solid waste problems.

This paper recommends a business model to recycle industrial wastes into clean energy for a better environment. Especially, it emphasizes on applications and advantages of finished product-recovered carbon black (rCB). This model also opens new research directions for renewable energy industry, new materials research, increases the value for society and developing countries in general, and for the company and investors in particular.

To promote energy saving and efficient energy using, to the demand of higher energy use of the national economy, and to protect the environment, rationally exploit of resources toward sustainable socio-economic development, the government need to adopt policies to encourage organizations and individuals to seek new renewable energy sources.

The government and authorities in Viet Nam and developing countries as well as developed countries can issue policies which can support renewable energy firms to protect environment. Channels of capital are also needed to encourage these companies to produce clean energy.

http://vnu.edu.vn/home/[ Ref ]

. Hirenkumar MP, Tushar MP (2012) Emission Analysis of a Single Cylinder Fuelled with Pyrolysis Oil Diesel and its Blend with Ethanol. IJEST 4: 2834 -2838.[ Ref ]

Rani S, Agnihotr R (2014) Recycling of Scrap Tyres. International Journal of Materials Science and Applications 3: 164-167.[ Ref ]

Elshokary S, Faraga S, Abuelyazeed O, Hurisso B, Ismail M (2018) Upgrading of Waste Tiers Pyrolysis Product: State-of-the-Art. International Journal of Waste Resources.[ Ref ]

Han J, Li W, Liu D, Qin L, Chen W, et al. (2018) Pyrolysis characteristic and mechanism of waste tyre: A thermogravimetry-mass spectrometry analysis. Journal of Analytical and Applied Pyrolysis 129: 1-5.[ Ref ]

https://doanhnhansaigon.vn/o-to/thi-truong-xe-hoi-the-gioi-tangtruong-bat-chap-cuoc-chien-thuong-mai-my-trung-quoc-1087727.html[ Ref ]

https://bnews.vn/thi-truong-o-to-viet-nam-co-the-dat-800-000-xe-trong-giai-doan-dan-so-vang/86935.html[ Ref ]

Roy C, Chaala A, Darmstadt H (1998) The Vacuum Pyrolysis of Used Tyres End use of oil and carbon black product. Journal of Analytical and Applied Pyrolysis 51: 201-221.[ Ref ]

https://ramboll.com/services-and-sectors/energy/waste-to-energy[ Ref ]

https://masdar.ae/en/masdar-clean-energy/technologies/waste-to-energy[ Ref ]

http://pyrolyx.com/en/pyrolyx-home.html[ Ref ]