Journal Name: Scholar Journal of Applied Sciences and Research

Article Type: Case Study

Received date: 07 May, 2019

Accepted date: 18 May, 2019

Published date: 27 May, 2019

Citation: Asari R (2019) Automotive Industrial Robot - Selection Criteria for Body Assembly Application. Sch J Appl Sci Res Vol: 2, Issu: 7 (06-08).

Copyright: © 2019 Asari R. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

In automotive manufacturing processes especially at Body Shop, industrial robots are widely used to increase productivity while maintaining desired quality standard and design specification in production line. The application is mainly on welding (spot / arc welding), sealant / adhesive application and material handling. Therefore, the selection of the robot types and brand are crucial in order to get best fit to the application at minimum cost.

Depending on area of application to the automotive body structure, generally, there are 2 types of industrial robots - shelf and floor mounted types. The practical way in robot selection method is by determining the robot specification that meeting process specification and requirement, then, cost evaluation is done by using Total Cost of Ownership (TCO) method [1]. The following table shows the comparison of robot specifications, initial and operational cost for different robot’s makers which gives general ideas on what to be taken into account during robot selection processes.

The robot’s specifications as stated on the table are suitable for spot welding and material handling applications. First thing to consider is process requirement on position’s accuracy. Process position’s accuracy (tolerance) has to be matched with robot’s repeatability. Then, other specifications such as maximum robot’s payload and ‘reach work space’ to be considered during robot’s selection process (Figure 1).

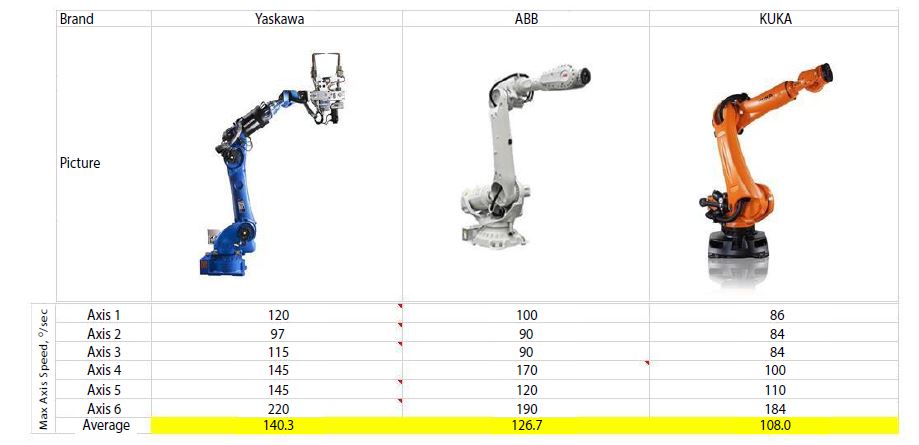

There are some robot’s specifications that are usually neglected but quite important especially when it comes into productivity and costeffective point of view. For example, for better productivity, faster robot axis speed is required to complete the process. The following tables shows the comparison of maximum robot axis speed for 3 different robot makers (Figure 2).

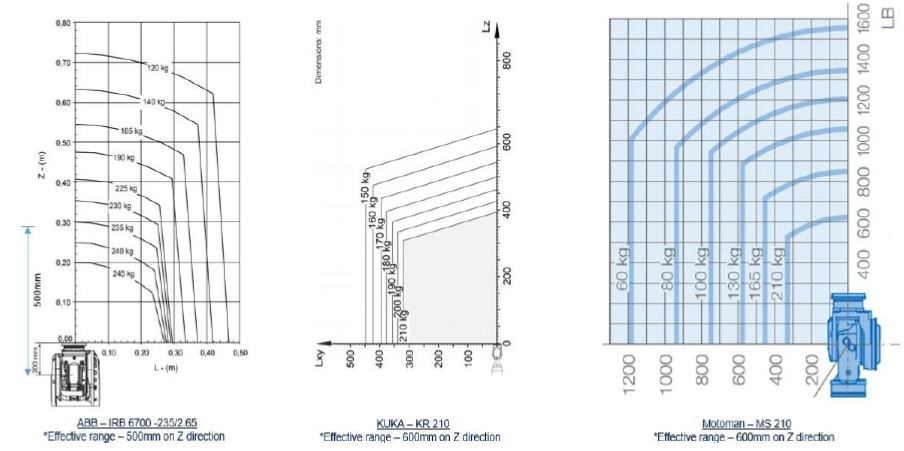

For cost effective point of view, maximum Center of Gravity (COG) range in robot payload diagram also quite important. The following table shows the comparison of robot payload diagram for 3 different robot makers (Figure 3).

Farther the effective range of allowable maximum payload in robot payload diagram, better the tool’s design flexibility and cheaper the tool’s material cost. For example, if the designed tool’s weight exceeds allowable effective range in robot payload diagram, there are 2 options available for designer, either to select higher robot payload spec or to use lightweight material for tool’s fabrication. Both options may increase the robot initial or purchase cost [2].

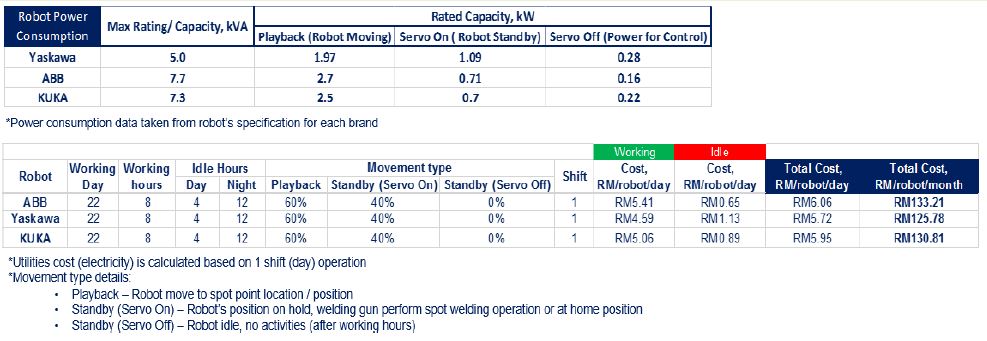

Estimating the operational cost of a robot is quite difficult but possible and usually neglected during robot selection processes. Other than robot Mean Time Between Failure (MTBF) value and spare part cost, robot power consumption during operation also can be estimated. The following tables shows the estimated robot power consumption comparison for 3 different robot makers (Figure 4).

Figure 1:Robot Specification Comparison.

Figure 2:Robot Axis Speed Comparison.

Figure 3:Robot Payload Diagram Comparison.

Figure 4:Robot Operational Cost Comparison.

In conclusion, it is easier to select robot that suit to the process requirement. But, when considering productivity and cost effectiveness, a lot of elements need to be considered during robot selection processes. It is recommended to evaluate robot total cost of ownership before finalizing robot selection to get clear picture of overall cost that need to be spent in robotic production line.