Journal Name: Scholar Journal of Applied Sciences and Research

Article Type: Research

Received date: 29 January, 2019

Accepted date: 22 February, 2019

Published date: 28 February, 2019

Citation: Ofeh ALE, Abdullahi MD, Bashir TM (2019) Evaluation of the Potential of Sugarcane Bagasse in Supporting the Growth of Two Fungal Species. Sch J Appl Sci Res Vol: 2, Issu: 2 (23-26).

Copyright: © 2019 Ofeh ALE. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Sugarcane bagasse is an agro-waste produced by sugar industries and can be burnt to generate energy in sugar and ethanol mills, which in turn causes environmental pollution. This residue from sugar industries is rich in complex materials and can be used for the growth of fungal species. The aim of the present work was to evaluate the potential of sugarcane bagasse (a low-cost substrate) in supporting the growth of two species of fungi (Alternaria and Microsporum). Proximate composition of sugarcane bagasse was determined following appropriate techniques and results obtained showed that it consists of cellulose: 46.5%, hemicellulose: 23.6% and lignin: 21.4%. Evaluation of the potential of the substrate was carried out by inoculating spores of the individual species of the test fungi into duplicate plates of sterilized sugarcane bagasse followed by incubation for a period of fourteen days. Both species were able to utilize this agro-industrial residue, producing fungal biomass with distinct features. Alternaria species was found to utilize 9% of the energy in the medium exhibiting faster growth as compared to 5.7% energy utilization by Microsporum species with slower growth after same incubation period. This result proves that sugarcane bagasse indeed, can be used as an alternative/substitute medium in place of expensive commercial media for the growth and production of fungal biomass for various uses.

Keywords

Sugarcane bagasse, Fungi, Growth medium, Low cost substrate.

Abstract

Sugarcane bagasse is an agro-waste produced by sugar industries and can be burnt to generate energy in sugar and ethanol mills, which in turn causes environmental pollution. This residue from sugar industries is rich in complex materials and can be used for the growth of fungal species. The aim of the present work was to evaluate the potential of sugarcane bagasse (a low-cost substrate) in supporting the growth of two species of fungi (Alternaria and Microsporum). Proximate composition of sugarcane bagasse was determined following appropriate techniques and results obtained showed that it consists of cellulose: 46.5%, hemicellulose: 23.6% and lignin: 21.4%. Evaluation of the potential of the substrate was carried out by inoculating spores of the individual species of the test fungi into duplicate plates of sterilized sugarcane bagasse followed by incubation for a period of fourteen days. Both species were able to utilize this agro-industrial residue, producing fungal biomass with distinct features. Alternaria species was found to utilize 9% of the energy in the medium exhibiting faster growth as compared to 5.7% energy utilization by Microsporum species with slower growth after same incubation period. This result proves that sugarcane bagasse indeed, can be used as an alternative/substitute medium in place of expensive commercial media for the growth and production of fungal biomass for various uses.

Keywords

Sugarcane bagasse, Fungi, Growth medium, Low cost substrate.

Introduction

Due to the rising cost of microbiological media, cost effective as well as efficient microbiological media should be designed as a solution to the above problem. This could be achieved through the use of agricultural waste which are abundant and readily available as raw materials for microbial media production. Utilization of some agricultural wastes as substrates for fungal cultures for the production of value-added products has been reported [1].

The sugarcane stem is milled to obtain the cane juice, which is either used for ethanol or sugar production [2], bagasse is obtained as a residue which corresponds to about 25% of the total weight and contains 60- 80% of carbohydrates [3]. About 54 million tons of sugarcane bagasse is produced annually throughout the world. In general, sugar factories generate approximately 270kg of sugarcane bagasse (50% moisture) per metric ton of sugarcane [4]. Sugarcane bagasse can be considered either as a waste affecting the environment when discarded as agricultural waste or burned for energy supply in sugar and ethanol mills [5,6]. Both alternatives are, however, pollutant and inefficient in making use of the chemical energy available in the biomass [7] and may have more valuable uses than the direct energy generation through combustion [8]. Sugarcane bagasse contains approximately cellulose 43.8%, 28.6% hemicellulose, 23.5% lignin and other components 2.8% [9]. Due to its high availability, it could serve as a substrate for microbial production of valueadded products, such as protein-rich animal feed, enzymes, amino acids, organic acids and compounds of pharmaceutical importance [10], and also source of carbon for the growth of filamentous fungi [11].

Sugarcane bagasse could be a material of choice for designing a new medium for fungi which could replace expensive media such as potato dextrose agar (PDA), Sabouraud dextrose agar (SDA), or cornmeal agar (CMA) as it is readily available in large volumes and also meets the requirements for fungal growth.

Materials and Methods

Collection and handling of samples

Sugarcane bagasse: Sugarcane bagasse was collected in clean polythene bags from markets in Zaria metropolis, Kaduna State, Nigeria. The bagasse was transported to the Department of Microbiology, Ahmadu Bello University, Zaria, where it was sundried and taken to the market for milling and then preserved in clean polythene bags until needed.

Fungal isolates: Alternaria and Microsporum species were obtained from the culture collection of the Laboratory of Microbiology of Ahmadu Bello University, Zaria, Kaduna State. The isolates were reactivated and re-authenticated following standard procedures (by culture and microscopy) and identification was achieved using an appropriate taxonomic guide of Mycology [12,13]. Reactivation was carried out by aseptically preparing fresh plates of PDA in accordance to manufacturer’s instructions. This was followed by inoculation of the isolates on the PDA plates aseptically and incubating at room temperature in a dark cupboard for a period of seven days. Re-authentication was carried out by slide culture method using lactophenol cotton blue inoculum preparation [14]. Microscopic features were compared with those on mycology atlas for identification. Authenticated isolates were sub-cultured on fresh PDA slants and incubated at room temperature in a dark cupboard for seven days.

Determination of the proximate composition of sugarcane bagasse

Moisture, ash, cellulose, hemicellulose, lignin, protein and lipid content of the sugarcane bagasse sample were carried out at Department of Food Science, Institute of Agricultural Research, Ahmadu Bello University, Zaria, following standard procedures of the Association of Analytical Chemist [15].

Preparation of fungal spore inoculum

Sporulated cultures of the fungal isolate grown on potato dextrose agar slants for seven days were used. Spores of the fungal isolates were picked using a sterilized inoculating needle. The spores were transferred into sterilized bottles containing sterile potato dextrose broth. The bottles were placed in a shaker and incubated at room temperature for a period of two days [16].

Evaluation of the potential of sugarcane bagasse in supporting growth of the test fungi

This was carried out by weighing 20g of sugarcane bagasse into four separate glass Petri dishes followed by supplemental addition of 200ppm of ammonium nitrate, magnesium sulphate and potassium hydrogen phosphate. The Petri dishes and their contents were autoclaved at 121℃ for 15 minutes. Ten milliliter spore suspension of isolates of Microsporum and Alternaria species were aseptically inoculated into duplicate plates of the freshly sterilized sugarcane bagasse. All inoculated plates were incubated aerobically in dark cupboard under ambient laboratory conditions for fourteen days with continuous monitoring for appearance of fungal growth. The cultures were then harvested dried and weighed using a top loading balance (Mettler PM16-K) to obtain the dry weight of the partially digested bagasse [17].

Results

Proximate composition of sugarcane bagasse

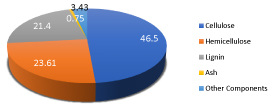

Result of proximate analysis of samples of sugarcane bagasse revealed that it is composed of moisture (3.52%), ash (0.75%), protein (4.81%), fat (0.2%), carbohydrate (64.7%) and crude fiber (26.02%) as indicated in Table 1. Further analysis of the crude fiber components showed that, it is made up of cellulose, hemicellulose, lignin, ash and other constituents to be 46.5%, 23.61%, 21.4%, 0.75% and 3.43% respectively (Figure 1).

Table 1: Proximate composition of sugarcane bagasse.

| Parameters | Composition (%) |

|---|---|

| Moisture | 3.52 |

| Ash | 0.75 |

| Protein | 4.81 |

| Fat | 0.20 |

| Crude Fiber | 26.02 |

| Carbohydrate | 64.70 |

Figure 1: Crude fibre contents of sugarcane bagasse.

Evaluation of the potential of sugarcane bagasse in supporting growth of the test fungi

The capacity of sugarcane bagasse to support the growth of the two fungal species used in this study was demonstrated as visible growth of each with the bagasse serving as substrate. Growth of Alternaria species was rapid with initially olivaceous green to black surface coloration but turned grey with age of the culture (Figure 2a) as against the coloration exhibited by the un-inoculated bagasse (Figure 2b). On the other hand, growth of Microsporum species was slow at first, exhibiting white/whitish yellow, flat, cottony or wooly surface appearance (Figure 2c). In general, the bagasse as substrate appeared to support a more luxuriant growth of Alternaria species as compared to Microsporum species under similar incubation conditions. This is further demonstrated by the proportion of the bagasse utilized by the two fungi during the fourteen days’ period of growth (Table 2).

Table 2: Percentage of sugarcane bagasse to growth of Alternaria and Microsporum species over 14 days’ period.

| Fungi Tested | Weight of sterile bagasse (g) |

Weight of bagasse after fungal growth (g) |

% of bagasse utilized for growth |

|---|---|---|---|

| Alternaria species | 297. 3 | 270.6 | 9.0 |

| Microsporum species | 303.5 | 286.1 | 5.7 |

Figure 2a: Alternaria species growth on sugarcane bagasse medium (incubation period: 14days).

Figure 2b: Un-inoculated sugarcane bagasse medium.

Figure 2c: Microsporum species growth on sugarcane bagasse medium (incubation period: 14days).

Discussion

The proximate analysis of sugarcane bagasse used in this study suggest that sugarcane bagasse has the potential use as a suitable and cheap medium for the growth and generation of biomass of filamentous fungi such as Microsporum and Alternaria species. This view is supported by the high proportions of cellulose (46.5%), hemicellulose (23.61%), lignin (21.4%), carbohydrate (64.7%), protein (4.81%), fats (0.2%), ash (0.75%) and other components (3.43%) making up the proximate composition of the bagasse. These components have been used as major constituents of several laboratory media used for the cultivation of filamentous fungi in the laboratory [18]. The high content of carbohydrate (64.7%), protein (4.81%), lipid (0.20%) and ash (0.75%) in the bagasse used in this study, strongly suggest that it could provide the energy, carbon, nitrogen, phosphorus and sulphur which constitute important requirements for growth of most fungi [18]. This implies that, sugarcane bagasse could provide alternative growth medium on which large quantities of fungal biomass could cheaply be generated for various uses. The low moisture content is an indication that the substrate is of good yield and of high quality as moisture content is used to assess the shelf life and quality of substrates. The ash content shows that the substrate indeed, contains a reasonable amount of mineral contents as it always represents a rough measure of the inorganic mineral elements in a sample such as calcium, sodium, potassium and chloride. The lower the ash content, the higher the quality of the material [19].

Similar results were obtained by Luz et al. [9] who reported values of 43.8%, 28.6%, 23.5%, 1.3% and 2.8% for cellulose, hemicellulose, lignin, ash and other components respectively. However, Betancur et al. [3], reported values of 35%, 25%, 22% and 20% for cellulose, hemicellulose, lignin and ash respectively while Soliman et al. [20], reported 45%, 28% and 18% for cellulose, hemicellulose and lignin. The difference in variation could be due to the ratio/proportion of various constituents of biomass materials which differ greatly among biomass categories and also from species to species [21].

The capacity of sugarcane bagasse to support the growth of Alternaria and Microsporum species as demonstrated on Figure 2a and 2c attest to the fact that the constituents of the bagasse can supply adequate amounts of nutrients essential for their growth. The ability of these fungal species to grow and produce measurable amounts of biomass at the expense of sugarcane bagasse on the other hand, indicates that these fungi species possess the requisite enzymes enabling them to utilize the available carbon, nitrogen, sulphur and phosphorous for cellular growth [22]. Although, both fungal species actively grew and produced measurable biomass on sugarcane bagasse medium, Alternaria species was found to exhibit faster and more luxuriant growth compared to Microsporum species. Also, higher proportion of the bagasse was found to have been lost following the growth of Alternaria species (9%) as compared to 5.7% recorded following the growth of Microsporum species over the same period of incubation. This observation could be attributed to several factors that may include the slow ability of Microsporum species to hydrolyze carbohydrate polymers (hemicellulose, cellulose and lignin) found in sugarcane bagasse [23-25].

Conclusion

Sugarcane bagasse contains complex lignocellulosic material that can be used as low-cost energy and carbon source for fungal cultures. The fact that sugarcane bagasse supported the growth of the fungi species under study suggests that it could provide a cheaper alternative to costly commercial laboratory media for large scale production of fungal biomass for various uses.

There are no references