Journal Name: International Journal of Food and Bioscience

Article Type: Research

Received date: 23 April, 2018 Accepted date: 11 May, 2018 Published date: 23 May, 2018

Citation: Hailu Z, Assefa B (2018) Production and Characterization of Beer from Kodome Sorghum. Int J Food Biosci Vol: 1, Issu: 1 (19-24).

Copyright: © 2018 Hailu Z, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

The study was conducted to produce and characterize beer from Kodome Varity of sorghum. The sorghum was collected from Enderta which is located in southern part of Tigray, with complete randomization sampling technique. The beer was produced from sorghum grain with brewing process involves malting, mashing, wort boiling, fermentation and packaging. The gelatinization temperature of sorghum starch samples was determined and results ranged between 80 0C. The experimental design was designed using randomized block design to investigate the effects of temperature, time and pH on quality attributes bitterness of the product. The products were beer and or with and without caramel. Hence, the effects of process variables on finished beer were conducted such as pH, bitterness, color, polyphenols, alcohol content (v/v), and carbon dioxide (CO2), Original extract (OE), density, real extract, alcohol (w/w), haze value, Ea (app extract), and Concentration of sugar. The results showed that 4.53, 9.854BU, 7.5EBC, 59.8272mg/L, 4.78%v/v, 3.803mg/L, 10.36%, 1.0049g/cm3, 2.92%w/w, 4.78%v/v, 0.165EBC, 2.15%w/w and 0.99 ºbrix respectively. Generally, the beer produced at grist malt size 0.2mm and mash temperature of 80 ºC had great sensory acceptance. Finally, it can be concluded that the mash for 1.30 hrs. 250 gram of 0.2mm size malt grist and 2000ml hot water at the end of the mashing add 4 gm of hop and ferment then a flavored and tasty beer can drink and get all the nutritional values of sorghum.

Keywords

Kodome Sorghum, Beer, Caramel, Bitterness.

Abstract

The study was conducted to produce and characterize beer from Kodome Varity of sorghum. The sorghum was collected from Enderta which is located in southern part of Tigray, with complete randomization sampling technique. The beer was produced from sorghum grain with brewing process involves malting, mashing, wort boiling, fermentation and packaging. The gelatinization temperature of sorghum starch samples was determined and results ranged between 80 0C. The experimental design was designed using randomized block design to investigate the effects of temperature, time and pH on quality attributes bitterness of the product. The products were beer and or with and without caramel. Hence, the effects of process variables on finished beer were conducted such as pH, bitterness, color, polyphenols, alcohol content (v/v), and carbon dioxide (CO2), Original extract (OE), density, real extract, alcohol (w/w), haze value, Ea (app extract), and Concentration of sugar. The results showed that 4.53, 9.854BU, 7.5EBC, 59.8272mg/L, 4.78%v/v, 3.803mg/L, 10.36%, 1.0049g/cm3, 2.92%w/w, 4.78%v/v, 0.165EBC, 2.15%w/w and 0.99 ºbrix respectively. Generally, the beer produced at grist malt size 0.2mm and mash temperature of 80 ºC had great sensory acceptance. Finally, it can be concluded that the mash for 1.30 hrs. 250 gram of 0.2mm size malt grist and 2000ml hot water at the end of the mashing add 4 gm of hop and ferment then a flavored and tasty beer can drink and get all the nutritional values of sorghum.

Keywords

Kodome Sorghum, Beer, Caramel, Bitterness.

Introduction

Sorghum is the grain of choice to produce traditional cloudy and opaque beers throughout sub-Saharan Africa. The key ingredient of these beers is sorghum malt, which provides hydrolytic enzymes (especially amylases) to ferment sugars into ethanol and carbon dioxide. Sorghum is used for food, fodder, and the production of alcoholic beverages. Sorghum ranks fifth in the world cereal production, and as of 2008 the world annual sorghum production stood at 65.5 million tons. Several improved varieties are released every year by sorghum breeders. More than 7000 sorghum varieties have been identified [1]. It is typically an annual, but some cultivars are perennial. It is an important food crop in Africa, Central America, and South Asia [2]. Sorghum is a large variable genus with many cultivars.

The method employed in brewing sorghum beer here involves, malting, mashing, wort boiling with hops, fermentation, (using brewer’s yeast and baker’s yeast) and packaging. The tropical sourced hop extracts used here is aroma flavor and bitterness which has been found to contain an anti-bactericidal agent which is capable of extending the useful life of these indigenous beers [3]. Nutritionally, sorghum protein as other cereal proteins are limited in amino acids, lysine, threonine, tryptophan and methionine. The color of sorghum grains varies from white to dark brown depending on the phenolic pigments present. Brown kernel sorghum grains usually have high tannin contents [4].

Generally, the sorghum is small-grained, annual, warmweather cereals belonging to grass family, easily available and cheapest starting raw material. They are highly tolerant of extreme weather conditions such as drought and are nutritious compared to the major cereals such as rice, barley and wheat.

Beer can also prepare from cereals, especially from the more nitrous cereal of tropics and subtropics region which is, sorghum. This cereal is commonly known as-Mashila in Ethiopia and some people. Sorghum beer is not known in our country so the purpose of this study will be full fill the limitation of the beer, by producing and characterizing of beer from Kodome variety of sorghum which will be collected from southern tigray, Enderta.

Methods and Materials

Sample collection and preparation

Kodome Varity sorghum was collected from Enderta wereda, through randomly collected from the farmers and transported to Adigrat university Chemical Engineering laboratories through plastic package and it clean and sieved the raw material. Grade the sample in to different plastic bag to study the processing and malting effect. The analysis of the sorghum and its product was done at APF and Raya brewery Plc. Laboratories.

Methods of analysis on raw material

Checking germination energy of sorghum: About 500 individual grain of sample raw sorghum was transferred into a funnel standing in tap water (to ensure complete flooding of the grains) at 20 ºC The water was removed after steeping for 3 hrs. The grains were covered with what man’s filter papers and the funnel itself covered with a glass plate. The steeping was repeated for 2 hrs. after 20 hrs. from the beginning of the test. The grains were again covered with filter paper and the funnel with glass plate. After 72 hrs. from the beginning of the test, the funnels were emptied and the number of non-germinated grains counted. Average result of the two counts (of the lots) after 72 hrs. was obtained. The formula below was used to calculate the Germination Energy (GE): (Figure 1)

Figure 1: No-germinated and germinated grain.

Where: N = number of non-germinated grains after 3 consecutive days.

Determination of germination capacity: This is an attempt to quantify the percentage of viable grains within a sample. About 200 uniform sized and clean grains were select and steeped 200ml of 0.75% hydrogen peroxide (h2o2) solution and incubated for two (2) days at a temperature of 21ºC. At the end of the 2 days, the grains were strained and steeped again in 200ml of h2o2 also at 21ºC for further 24 hours.

The germinated grains were then counted and the germination capacity calculated using the formula:

Where: n = grains that did not show roots

Moisture content of sample: Moisture content was measured by using 250 g malt should weigh out and put into a metal or glass container and placing in calibrated oven at a temperature of 105ºC and measuring the moisture content for 30,60,90, and120 min.

Moisture [%] was computed by using equation:

Where W1 is the weight of the sample before dry, W2 is the weight of the sample after dry (30, 60, 90, and120 min.)

Determination moisture content during steeping: The moisture content of the sample during steeping was determined by weighing using the following formula were taken from the sample for % Moisture content determination.

Where W1 is the weight of the sample before steeping, W2 is the weight of the sample after day (8, 16, 20 hours).

Determination of Malting Loss:

Total malting loss was calculated by using he following formula

Where: W1=initial weight, W2=weight after removing growth portion

Experimental design and process technology

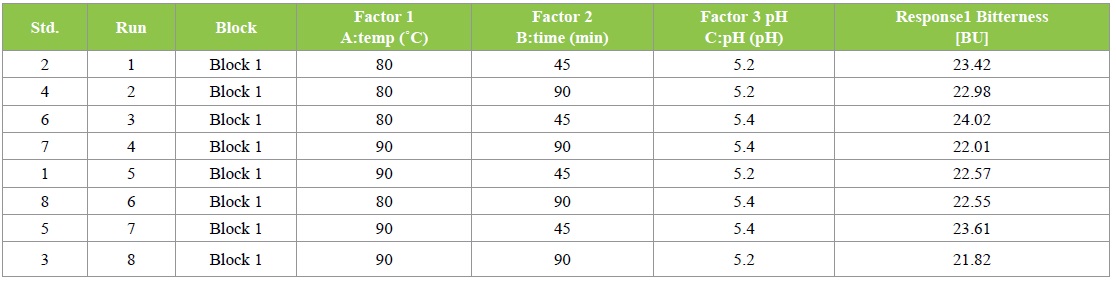

Experimental design: Experimental design selected for this study was a two Full-Factorial analysis with two level of treatment for comparative experiment and the main parameter was beer bitterness gained. The experiment was analyzed by the Design Expert software 6.0.8 and the study conducted to develop and evaluate wort quality. It was also used to identify the relationship existing between the dependent responses (beer bitterness) and independent process variables as in the brewing process. The three independent variables or factors studied were: brewing temperature (80 ºC and 90 ºC), time (45min and 90 min), pH (5.2 and 5.4) for actual variable levels. For each factor, an experimental range was adjusted based on the results of literature data and on the performance of preliminary experimental trials. These three factors: temperature, pH and time were selected as independent variables, because of their influence on brewing process. In this study, hop ratio was controlled as constant during each brewing process. Therefore, in this work, Physio-chemical analysis; sensory quality evaluation and microbiological analysis are conducted in the Raya brewery Plc which means comparisons are performed analysis of variance (ANOVAs) for all data for each processing stage and the influence of process variables on bitterness of beer will be analyzed a 8 Full-Factorial experiment. To do these, design expert 6.0.8 software package has been employed.

Process technology

Malting: The 250g grain was made with different parameters (time, extent of aeration, temperature) by steeping, germination and kilning and their main nutritional values were determined. Steep with water contained plastic for 20hrs. was suitable for the next process. After steeping stage, sorghum was germinated up to 6 days. It is carried out at room temperature and involved the use of fibered bag (Kasha). Another pre- wet Kasha was used to cover the grains. This had been continuously spray water and well spread out on the laboratory bench. At the end of the period the germinated grains were hand-rubbed to break-off the roots let’s and then kilning of the germinated grains was carried out for 16 hours at 50 ºC in an oven.

Milling: Grist was made from the malted sorghum grains by grinding them by mortar and pestle to a fairly coarse texture. The desired particle size for this study was 0.2 mm diameter. Sieving analysis of the milled malt was performed in order to achieve the desired particle size distribution.

Mashing condition: The grist was stirred with warm distilled water at 65 ºC ± 3 and 80 ± 3 ºC then 0.3g CaCl2 and 0.2ml HCl were added. It was mashed in an intensive mashing process with Brew pot. Saccharification test was carried out by the addition of few drops of iodine solution to the mash sample. This was to check conversion of starch to sugar. Change in color to blue black indicated a good Saccharification, spent grain was separated using domestic sieve size 125μm to obtain sweet wort.

Wort boiling: Sweet wort was obtained and boiled at temperature of 98oc for 1.5 h during which 4g hop extract were added step by step early, in the middle, at the end for the purpose of bitterness, flavor and aroma respectively.

Sedimentation (whirl pool): At the end of the boil, solid particles in the hopped wort are settled for 30 min in funnel or beakers at temperature of 90 ºC.

Cooling: The bitter wort was cooled to 8 ± 2 °C using ice bath with pure sand and pitched. Pitching was carried out by adding to the bitter wort, about 0.0125ml liquid Saccharomyces cerevisiae was added.

Fermentation: Primary fermentation was then done at 14 ± 2 °C for a week to obtain ‘young’ beer using sealed fermentation bucket at the head and fitting with tube and the tube was putting in water container bucket after the fermentation bucket. The matured lager beer was then filtered into sterile bottles through poly ester cloth. It was corked, left for one hour and pasteurized at 65 ± 3 ºC for 45 minutes.

Product characterization

Total Polyphenols (Spectrophotometer method): 10ml of the beer sample was pipette out and 8ml of CMC/EDTA reagent into a 25ml volumetric flask Stopper and thoroughly mix the contents. Then adding 0.5ml ferric reagent to the measurement sample and thoroughly mix, and 0.5ml ammonia reagent admix was done make up to 25 ml (or 50 ml) with water and mix. After kept the measurement sample for 10 minutes’ measurement the absorbance was done in a 10ml cuvette using a spectrophotometer at 600 nm. Ensure that the solution to be measured was cleared.

Mix 10 ml of the sample of beer and 8 ml CMC/EDTA reagent in a 25 ml or 50 ml of volumetric flask and 0.5 ml of ammonia reagent was added and mix well. Allowed to stand for 10 minutes and measured the absorbance.

Calculate the content of polyphones using the formula

Where, A = Absorbance at 600 nm

F = Dilution factor

Determination of Bitterness

Beer is degassed without the loss of foam. The bitter substances are mainly iso-α-acids, that are extracted from acidified wort or beer with isooctane and the absorbance at 275 nm is measured. Hence, 300ml of sample was stirred by magnetic starrier for five minute and10ml of sample was taken into 1the 100ml flask. Then 1ml of 3N HCL and 20ml standardized of iso-octane was added. The final solution was mechanical shaker for 15minutes. Finally, the shake solution was rested for 10minutes and the bitterness measured by using spectrophotometers at 320nm.

Expression of Results

Color and gas analysis: Color measurement was done based on European Brewery Convention method using the spectrophotometer. Fifty milliliter samples of the filtered wort produced was taken and re-filtered using whatman’s number 4 filter paper. The first 20ml was discarded and remaining was collected. The spectrophotometer was set at 430nm wavelength. Blank test was first done with distilled water and used to adjust the absorbance to 0.000. After rinsing the cuvette with the bright malt wort, the absorbance of the sample was determined at 430nm.The sample was diluted with distilled water to 1:5 wort: water ratio.

The color of the sample was then calculated using the equation below:

- Where,

- C= the color in EBC units

- 25=the multiplication factor

- A= absorbance at 430nm in 10mm cuvette

- F= dilution factor.

Sensory quality analysis

An acceptability and flavor profile (color, mouth feel, bitterness and foam stability) tasting was conducted on 2 beer samples. The sensory analysis was conducted using 4 member-trained panelists using the sensory evaluation form in appendix F. The panel judges constituted two who are staff and currently have been working in Raya Brewery and who has experiences and familiar of beer drinking and the other two were trainee students from different university. The performance of panelist was check by comparing the sensory analysis result and instrumental result. The samples were served at 15°C so that panel members could easily pick flavor notes. Samples were served in clean and odorless drinking glasses. All assessors had one score sheet for two samples and tasted all samples with in 15min. The hedonic scale (4 levels) was designed as 0 to 4 scores for evaluate external appearance (color intensity and turbidity), smell (hop, malt, toasted, caramel, odor intensity), mouth feel (viscosity, astringency) and gustatory sensations (sour, bitter and sweet taste, intensity and persistence). Panelists were instructed to rinse their mouths with water before starting and between sample evaluations. Parameters for evaluation are shown in the questionnaire in appendix F. The ratings of each sensory attribute were converted to numerical scores and the numerical scores were collected for statistical analyses.

Results and Discussion

The result and discussion includes hot water extract at various mashing temperatures, PH for mashing, effect of temperature, time and pH on the quality bitterness of the product and sensory evaluation.

Hot water extract at various mashing temperatures

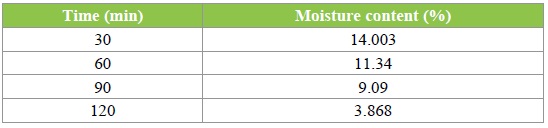

The hot water extracts were studied at two different temperatures, i.e. 65 ºC, 80 ºC. (Table 3.1) shows the response of the resulting wort to the iodine test, which indicates the presence or absence of starch. At 65 ºC all the varieties tested positive to iodine, suggesting the incomplete hydrolysis of starch into sugars. This means that at this temperature, the starch contents are not gelatinized. When the mashing was continued at 80 ºC but without the addition of enzymes; the resulting wort tested negative to iodine; indicates complete starch hydrolysis.

Table 3.1: Response of wort produced at different Mashing temperatures to iodine tincture test.

Note: Positive = indicates incomplete hydrolysis of starch.

Negative = indicates complete hydrolysis of starch.

pH for mashing

pH is very important during mashing since mashing is entirely an enzymatic process; therefore, it plays an important role. It was interesting to note that the mash pH of sorghum variety studied (except barley malt) was within the range (5.39-6.09), which fall within the required mash pH (5.6 ± 0.4), even though 6.09 is slightly on the higher side. Therefore, the pH of sorghum was adjusted to 5.3 to 5.6 with different ratio of hydrochloric acid, at all the mashing temperatures. Therefore, in brewing with sorghum, there must always be correction for pH.

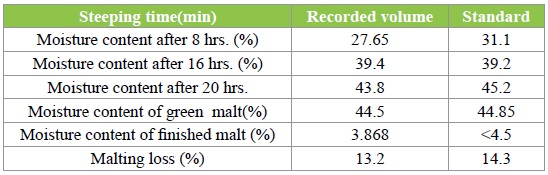

Moisture content

The moisture content can be determined at 105 ºC.

From table 3.2 the moisture content of sorghum malt was determined at 105 ºC for 120 min at 30 min time interval. As shown the result above the moisture content of the malt was decreased as time was increased.

Table 3.2: Moisture content of sorghum malt.

Effect of steeping process

This was analyzed at 20 hrs. at room temperature (Table 3.3)

Table 3.3: Moisture content during steeping.

The moisture content was measured during steeping at room temperature in the time interval of 8, 16, and 20 hours. The moisture content was increased as time of steeping was increased. As the above figure shows our experimental result was approximately equal with the standard value.

Chemical analysis on finished products

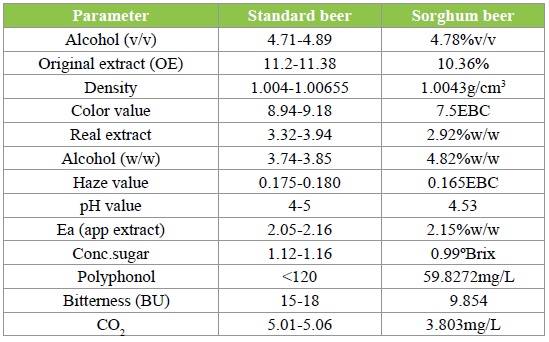

The Original gravity (OG), specific gravity (SG), apparent extract, real extract, alcohol content (v/v), density, conc. sugar, CO2 and haze value were measured using the Anton Paar Beer analyzer. All the analysis was carried on Raya brewery. (Table 3.4)

Table 3.4: Summary of finished sorghum beer analysis.

The above figure 2 shows that the final sorghum beer analysis and this analysis were carried out by Anton par analyzer. From above the result of all experimental runs, finished beer analysis ethanol levels was generally very high, because of result of high gravity brewing results of bitterness in finished beer analysis can be performed but the bitterness value is smaller than barley beer because this is on the type of hop that can be used. But the other parameters are almost approximate with barley standards. (Table 3.5, 3.6).

Table 3.5: Experiments done in laboratory scale.

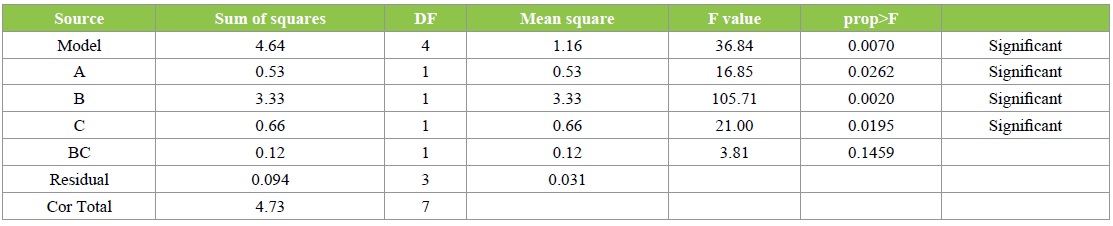

Table 3.6: Analysis of variance (ANOVA) on bitterness.

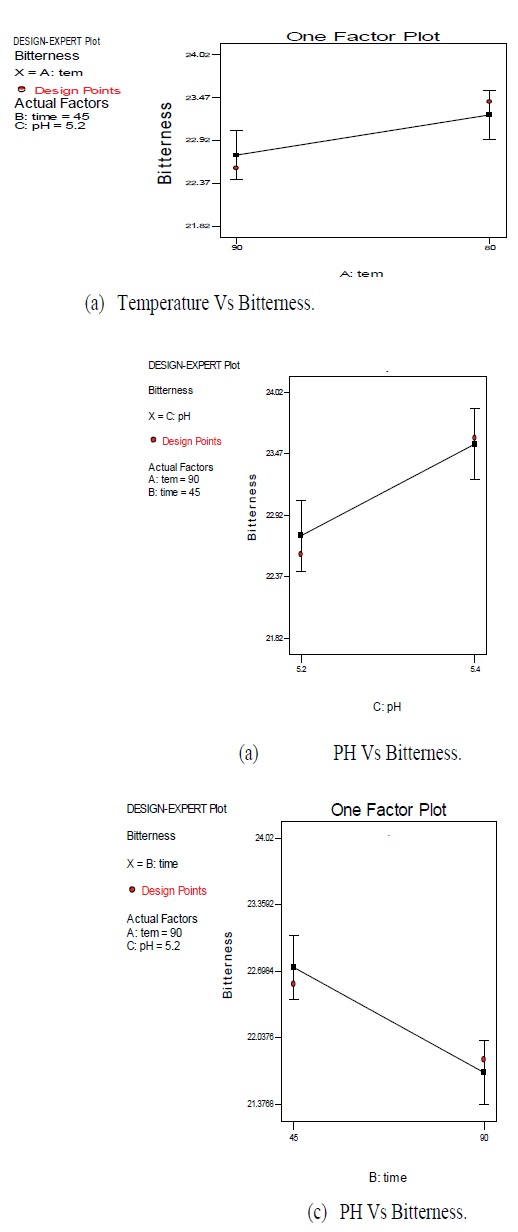

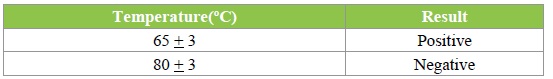

Figure 2: Process parameter effect on bitterness.

The Model F-value of 36.84 implies the model is significant. There is only a 0.70% chance that a “Model F-Value” this large could occur due to noise.Values of “Prob > F” less than 0.0500 indicate model terms are significant. In this case temprature, time, pH are significant model terms. Values greater than 0.1000 indicate the model terms are not significant.

The above figure 2 a, b, c showed that the process parameters (temperature, Time and pH) that affect the bitterness of beer are temperature, pH, and time. Thus parameters are significant effect on bitterness of beer. Thus, as pH increase the bitterness of the beer increase and as time and temperature increase bitterness decrease. From these the bitterness of the beer was inversely proportional with time and temperature directly proportional with time.

Conclusion

The utilization of grist ingredients derived from sorghum sources can be tested furthermore; malts made of them are suitable for application in brewing. The quality and quantity of their components meet requirements of yeast and an undisturbed fermentation. Since our investigation has proved that the nutritive value and brewing technological value of malts made of gluten-free cereals fall behind that of regular barley malt, it is advisable to use glutenfree adjuncts (invert sugar syrup) and industrial enzyme preparations to increase extract content of wort. Two strain of yeast were screened for fermentation and fermentation period were carried out. The alcohol content was increased accordingly with the fermentation time. The product was further pasteurized at 65 ºC for 45 min, carbonated and stored at 4 ºC and used for further analysis. The beer was found to have a pH of 4.12, an alcohol content of 4.78 per cent and the Color of the beer were 7.5 EBC. Similarly, the commercial brand of beer (barley beer) was also tested for the above mentioned parameters which did not differ much with that of sorghum beer. The beer with wet hop has best flavored, aroma, and mouth fullness product has best overall acceptability by panelists with an overall acceptability of 2. From the organoleptic evaluation, it was found that sorghum beer was comparable with that of commercial beer except differing slightly color, acidity and flavor which can be further improved. Thus, grains of sorghum can be used for commercial beer production as an alternate to barley. Production of beer from sorghum is feasible from the economic point of view in that its internal rate of return provides a return greater than the current rate of return. Moreover, the payback time is less than two years.

Competing interests

The authors declare that they have no competing interests.

Knudsen E, Kirleis A, Eggum B, Munck L (1988) Carbohydrate composition and nutritional quality for rats of sorghum prepared from Decorticated White and Whole Grain Red Flour. The Journal of Nutrition 118: 588-597. [ Ref ]

Abiodun A (2002) The effect of kernel size and texture in malting properties of sorghum. The Journal of food Technology in Africa 7: 78-81. [ Ref ]

Okafor N (2007) Modern Industrial Microbiology and Biotechnology. Enfield (NH): Science publishers. Scotland, pp: 109-234. [ Ref ]

Kent N (1983) Technology of cereals; An introduction for students of food Science and Agriculture. (3rd Edition). Newville: Pergramon press ltd. [ Ref ]