Journal Name: International Journal of Food and Bioscience

Article Type: Research

Received date: 03th-May-2018

Accepted date: 17th-May-2018

Published date: 23rd-May-2018

Citation: Sun L, Liu S, Fan Z, Li Y, Wang J, et al. (2018) The Impact of Storage Temperature on Fruit Quality and Chilling Injury of ‘Okubao’ Peaches. Vol: 1, Issu: 1 (12-18).

Copyright: © 2018 Sun L, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

In the present work, chilling injury (CI) incidence and quality parameters were analyzed in peaches stored at 0 °C, 2 °C, 5 °C and 8 °C for 28 days, to evaluate the effects of four different temperatures on the keeping quality of ‘Okubao’ peach. The extreme susceptibility of ‘Okubao’ peach to CI at 5 °C was confirmed by extensive woolliness and decay. Peaches stored at 5 °C develop noticeable CI symptom after one to two weeks, while significantly less woolliness occurred after storage 8 °C, the temperature at which the highest rate of decay was found. Minimum loss of weight and firmness, optimum sensory quality were obtained by the prolonged storage at 0 °C. 0 °C was the most effective treatment in alleviating chilling injury by controlling membrane permeability, inhibiting respiration rate and slowing down polyphenol oxidase (PPO) and peroxidase (POD) activities. Results indicated that fruit held at 0 °C can be stored for at least four weeks, and possibly five weeks without much injury.

Keywords

‘Okubao’ peaches, Chilling injury, Woolliness, Cold storage, Quality.

Abstract

In the present work, chilling injury (CI) incidence and quality parameters were analyzed in peaches stored at 0 °C, 2 °C, 5 °C and 8 °C for 28 days, to evaluate the effects of four different temperatures on the keeping quality of ‘Okubao’ peach. The extreme susceptibility of ‘Okubao’ peach to CI at 5 °C was confirmed by extensive woolliness and decay. Peaches stored at 5 °C develop noticeable CI symptom after one to two weeks, while significantly less woolliness occurred after storage 8 °C, the temperature at which the highest rate of decay was found. Minimum loss of weight and firmness, optimum sensory quality were obtained by the prolonged storage at 0 °C. 0 °C was the most effective treatment in alleviating chilling injury by controlling membrane permeability, inhibiting respiration rate and slowing down polyphenol oxidase (PPO) and peroxidase (POD) activities. Results indicated that fruit held at 0 °C can be stored for at least four weeks, and possibly five weeks without much injury.

Keywords

‘Okubao’ peaches, Chilling injury, Woolliness, Cold storage, Quality.

Introduction

Peach is a popular fruit worldwide with its great coloration, high sweetness, desirable flavor and nutritional value [1]. In 2016, the estimated production of peach and nectarine worldwide totaled over 20 billion tons, and China accounts for about 66% of the world with a production value of 13.2 million tons [2]. Unfortunately, peach fruit is generally characterized by high perishability and a relatively short storage potential owing to rapid ripening and senescence, excessive softening and decay.

The ideal peach storage temperature is 0 °C to 1.7 °C. Holding peach at this temperature will minimize deterioration resulting from internal browning and retard moisture loss and spoilage [3]. Refrigerated storage is therefore commonly used to maximize their postharvest life, but due to the extreme perishability and susceptibility to chilling injury (CI) at prolonged exposure to temperatures below 10 °C, or more severe under 2.2-7.6 °C, peach easily develops woolliness, reducing consumer acceptance and limiting the commercial life [4]. The susceptibility to CI is a primary factor that determines how long the fruit remain marketable after harvest. The storage potential based on CI and the type of symptoms depend on cultivar [5], maturity stage [6] and the storage temperature, ranging from one week at 5 °C to five weeks at 0 °C [7]. The market life is dramatically reduced to one to two weeks due to the development of browning and mealiness when susceptible peaches were exposed to 5 °C, but the expression of these symptoms was delayed and less severe when fruits stored at 0 °C [8]. Thus, peaches should be stored at 0 °C than at 5 °C, in agreement with previous reports [9- 12]. In some cases, however, some peach cultivars, such as ‘Elberta’, develop chilling injury at 0 °C and must be stored at 5 °C [13]. Temperatures near 2 °C are preferred by shipping cooperatives in Spain [14]. It has been observed that temperatures above 5 °C result in rapid tissue softening and quicker ripening [15,16]. Therefore, the objective of this work was to explore the proper temperature at which ‘Okubao’ fruit can be held with least danger of either internal breakdown or over-ripening.

Materials and Methods

Fruit harvest, treatment and storage conditions

Peach fruits (Prunus persica L. Batsch cv. ‘Okubao’) were harvested at commercial maturity from a commercial orchard in Beijing, China, and immediately transported to the laboratory where sorted for uniformity of size, color and lack of defects. Peaches were packed in plastic boxes with the fruits touching (600×400×235 mm). After forced-air precooled to 5 °C, fruits were divided into four homogeneous groups of 120 fruits to be submitted to 0 °C, 2 °C, 5 °C, 8 °C for 28 days. Analyses were carried out initially and at 7 days’ interval for physicochemical measurements and sensory evaluation.

Weight loss, chilling injury, sensory quality, and decay assessments

Cumulative weight losses were expressed as percentage loss of original weight.

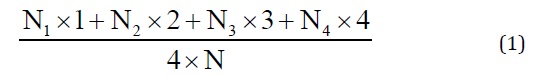

The degree of woolliness was evaluated visually based on flesh browning area after cutting the fruit in half along its equatorial axis and calculated as the percentage of browned fruit on a scale where 0 = no browning; 1 = less than 1/4 browning; 2 = 1/4-1/2 browning; 3 = 1/2-3/4 browning; 4 = more than 3/4 browning [17,18]. The woolliness incidence (WI) was expressed as follows:

where N = total number of fruits examined, and N1, N2, N3 and N4 were the number of fruits showing the different degrees of woolliness.

The sensory analysis was performed by a trained panel of five members. All fruits were evaluated for quality on a 1-9 scale, where excellent, freshly = 9; very good = 7; good, limit of marketability = 5; fair, limit of usability = 3 and poor, unusable = 1, where 6 is considered the minimum for salability [19].

Percentage of decayed fruit was calculated from the number of fruit that shown signs of decay over the initial number of fruit.

Color, firmness, soluble solids content (SSC), and total titratable acidity (TA)

External color was measure along the equatorial axes each fruit using CR-400 colorimeter, which provided L*, a* and b* coordinates. From these values, hue angle was calculated as h° = arctan (b*/a*) when a* > 0 and b* > 0. Chroma was expressed also as C* = (a*2+b*2)1/2.

Fruit firmness was determined with a penetrometer (TR-FT327, Italy) fitted with a 5-mm diameter plunger. Measurements were taken at two equatorial positions on each fruit after the skin was removed and results expressed as Newton (N).

Soluble solids content (SSC) was determined with a digital refractometer (Atago Co.Ltd., Tokyo, Japan), and results expressed as %.

Titratable acidity (TA): 10 grams of fruit pulp was taken from peaches and brought to a final volume of 100 ml by adding distilled water. A 20 ml sample was taken from the mixture and three to four drops of phthalein was used as indicator. This suspension was titrated with 0.1 mol·L-1 NaOH until a pink color. The results were expressed in terms of malic acid.

Extraction and measurement of ascorbic acid concentrations

Ascorbic acid content was determined by molybdenum blue colorimetric method according to the method of [20].

Physiological parameters

Five fruits were weighed and placed in 2 L jars, sealed for 2 hrs. to obtain gas samples. Gas samples (1ml) of the effluent air were withdrawn with a syringe from the head space and injected into a gas chromatograph Agilent Technologies 7820A, to determine the ethylene concentration. The results were expressed as μl·kg-1·h-1, according to the method of Li et al. (2012) [21].

Changes in the respiration rate of fruits within the period beginning with the harvest date till the end of storage life were determined as mg CO2·kg-1·h-1 using an infrared CO2 analyzer following the procedures previously described by [22].

Relative electrolyte leakage and malondialdehyde (MDA) content

Membrane permeability, expressed by the relative electrolyte leakage rate, was determined using a conductivity meter (Model DDS-11A, Shanghai Scientific Instruments Co., Ltd., Shanghai, China). Determination of membrane integrity was carried out according to a modified version of the method used by [23]. 18 slices, which were 10 mm in diameter and 2-mm thick, were obtained from 6 fruits and placed into tube containing 20 mL of deionized water. These were then incubated at 25 °C for 60 min. The resulting solution was then placed in a water bath (100 °C) for 30 min and cooled to 25 °C before the final conductivity (total electrolyte leakage) was measured. The percentage of electrolyte leakage was calculated as: (electrolyte leakage after 60 min submersion/ total electrolyte leakage) × 100%.

To analyze MDA content, 1 g of fresh tissue was homogenized with 5 mL of 100 g/L trichloroacetic acid and centrifuged at 12000×g for 20 min at 4°C. MDA content was determined by the method of [23] and expressed as μ mol/g fresh weight.

Polyphenol oxidase (PPO) and peroxidase (POD) enzyme activities

1 g of tissue was taken from 6 different fruits and homogenized in 5 mL of phosphate buffer. After centrifugation at 12000×g for 20 min at 4 °C, 2 mL supernatant was collected as enzyme extract. POD and PPO activities were assayed following the method of [23].

Statistical analysis

All statistical analyses were performed with the SPSS 19.0. Data were analyzed by one-way analysis of variance (ANOVA). Means were compared using least significant difference (LSD) test. Differences at P<0.05 were considered as significant.

Results

Sensory evaluation, decay, weight loss and chilling injury (Figure 1)

After 28 days of storage at the respective temperature, peach stored at 0 °C showed the highest score of sensory quality (Figure 1a). Even after 28 days at 0 °C, the average sensory quality of peach scored 6.5. Peaches were considered as acceptable after 21 days of storage at 2 °C, 5 °C, 8 °C. Significantly (P<0.05), peach held at 2 °Chad higher sensory quality than 5 °C and 8 °C. It is not recommended that temperature of 5 °C be used for the long storage of peaches based on increased risk of chilling injury development accompanied by a severe loss in sensory quality.

Figure 1: Sensory evaluation (a), decay (b), weight loss (c) and chilling injury (d) during 28 days of storage of ‘Okubao’ peach at four different temperatures.

With respect to decay incidence, results showed that decay increased with the progression of storage period (Figure 1b). No decay was observed in 0 °C up to 7 days of storage. After 14 days’ storage, only peach fruits at 5, 8 °C showed the rotting higher than 5% and was widespread after 28 days. At the end of storage, maximum spoilage (24.3%) was recorded in 8 °C stored fruits followed by fruits held at 5 °C. Similarly, to decay, significant increase in weight loss took place during the prolonged storage period with greater increase occurring at 5 °C and 8 °C (Figure 1c). Weight loss was less than 5.0% at all storage conditions until day 21 of storage, but it was affected by temperature and was greater at 8 °C than at 0 °C (P<0.05). By day 28, overall weight losses were 6.4%, 7.6%, 8.4% and 8.8% at 0 °C, 2 °C, 5 °C and 8 °C, respectively.

The degrees of woolliness were statistically different at different temperature and increased substantially as storage progressed (P<0.05). Peaches hold at 0 °C and 2 °C did not develop woolliness during the 14-day storage, but those exposed to 5 °C began exhibiting woolliness and the index increased thereafter. After 28 days of storage, all fruits developed wooly symptom, but the incidence was significantly reduced and delayed when fruits were stored at 0 °C. The peaches stored at 2 °C developed woolliness almost as fast as those at 5 °C. Although temperature of 8 °C provided successful control of cold storage disorders, the resulting over-ripening, senescence, and excessive softening were equally damaging. In summary, peaches should be stored for less than 14 days at 5 °C compared to 21 days at 0 °C to avoid development of woolliness.

Color (Figure 2)

With respect to color, lightness (L* value), redness (h° value) and intensity of color (C* value) of 0, 2 °C stored fruit were greater than that of 5 °C, 8 °C stored fruit during storage (Figure 2). L* and h° values decreased more rapidly at 5 °C or 8 °C than at 0 °C as the fruit turned darker red, which is undesirable to consumers. After 28 days of storage, fruit stored at 5 °C showed the typical browning associated with internal breakdown. This alteration was reflected by hue angles lower than those from fruit stored under 0 °C.

Figure 2: Lightness (L*), hue angle (h°) and chroma (C*) values during 28 days of storage of ‘Okubao’ peach at four different temperatures.

Firmness, SSC, TA and ascorbic acid concentration

The firmness loss rate was significantly different among temperatures (Tabel 1). Fruit harvested at 39.08 ± 1.53N became significantly soft after 28 days’ storage at 8 °C, decreasing by 83.5%. With woolliness of peaches at 5 °C, the firmness decreased rapidly after 14 days. However, the decrease was slowed by 0 °C, 2 °C, and peach decreased by 2.7% and 44%, respectively, after 21 days of storage.

Variations in content of SSC in the peach during storage showed an initial increase before a gradual decrease, whereas TA decreased continuously. The SSC in the peach stored at 0 °C, 2 °C, 5 °C, 8 °C was measured at 10.07%, 9.03%, 8.60% and 8.73% respectively, after 28 days’ storage. The TA value of peach fruit decreased rapidly at 5 °C, and to a greater extent at 8 °C. After 28 days of storage, the maximum acid (0.147%) was observed in 0 °C stored fruits, followed by 5 °C, 2 °C, 8 °C.

Ascorbic acid levels diminished rapidly over the 28 days’ storage period, at which less than 40% of the initial level was detected (Table 1). For all storage temperatures, loss of ascorbic acid concentration for peach exposed to 0 °C was reduced during the experiment, but there was a sharp decrease in those stored under 2 °C, 5 °C, 8 °C, especially at 8 °C. After 28 days, the total ascorbic acid content in peach held at 0 °C, 2 °C, 5 °C, 8 °C was 0.211, 0.132, 0.188, 0.157 mg/g, respectively. This level was clearly lower in peach with some degree of woolliness.

Table 1: Different Changes in firmness, SSC, TA and ascorbic acid concentration of ‘Okubao’ peach during 28 days of storage at four temperatures.

| Quality parameters | Temperature | 0d | 14d | 21d | 28d |

|---|---|---|---|---|---|

| Firmness (N) | 0°C | 39.08 ± 1.53 | 40.36 ± 1.96 | 38.03 ± 3.50 | 33.20 ± 3.08 |

| 2°C | 28.17 ± 3.30 | 21.87 ± 4.04 | 17.00 ± 5.93 | ||

| 5°C | 17.22 ± 3.77 | 14.63 ± 3.54 | 10.43 ± 4.01 | ||

| 8°C | 14.28 ± 1.92 | 13.52 ± 4.32 | 6.43 ± 0.64 | ||

| Total soluble solids (%) | 0°C | 9.40 ± 0.30 | 10.60 ± 0.15 | 10.23 ± 0.27 | 10.07 ± 0.28 |

| 2°C | 10.30 ± 0.18 | 9.23 ± 0.03 | 9.03 ± 0.17 | ||

| 5°C | 10.13 ± 0.03 | 8.97 ± 0.15 | 8.60 ± 0.26 | ||

| 8°C | 9.47 ± 0.27 | 9.00 ± 0.12 | 8.73 ± 0.47 | ||

| Titratable acidity (%) | 0°C | 0.312 ± 0.005 | 0.259 ± 0.012 | 0.177 ± 0.012 | 0.147 ± 0.008 |

| 2°C | 0.252 ± 0.011 | 0.145 ± 0.002 | 0.135 ± 0.005 | ||

| 5°C | 0.178 ± 0.005 | 0.146 ± 0.013 | 0.138 ± 0.005 | ||

| 8°C | 0.145 ± 0.011 | 0.141 ± 0.009 | 0.121 ± 0.009 | ||

| Ascorbic acid content (mg/g) | 0°C | 0.563 ± 0.003 | 0.451 ± 0.003 | 0.347 ± 0.003 | 0.211 ± 0.016 |

| 2°C | 0.434 ± 0.005 | 0.299 ± 0.004 | 0.132 ± 0.021 | ||

| 5°C | 0.402 ± 0.005 | 0.269 ± 0.001 | 0.188 ± 0.003 | ||

| 8°C | 0.404 ± 0.002 | 0.278 ± 0.002 | 0.157 ± 0.006 |

Ethylene production and respiration rate (Figure 3)

Ethylene production, which was about 0.011 μ L·kg-1·h-1 at the beginning of the experiment, increased immediately during the experimental period (Figure 3a). In peach fruit stored at 8 °C, the ethylene concentration increased rapidly during the first 7d to a peak value of 0.198 μ L·kg- 1·h-1, thereafter dramatically declined and then increased to the second peak on the 21st day. The maximum ethylene production was more than 2-fold higher and occurred earlier than 0 °C. During 28 days of storage at 5 °C, ethylene production of peaches was significantly higher than that of the 0 °C, 2 °C (P<0.05). The maximum production rates of fruits stored 0 °C, 2 °C, 5 °C occurred on day 21. Treating peach fruit with low temperatures significantly delayed the peak of ethylene production, moreover, it did affect the accumulative rate of production.

Figure 3: Ethylene production (a) and respiration rate (b) during 28 days of storage of ‘Okubao’ peach at four different temperatures.

The respiration rate was about 30.1 mg CO2 kg-1·h-1 at harvest and it sharply increased, peaked on day 7, to value of around 95.6 mg CO2 kg-1·h-1 and then gradually decreased of the 5 °C stored fruit. The climacteric respiratory peak of fruits stored at 0 °C, 2 °C, 8 °C was observed on the 14th day, peaked at 38.3, 82.6, 97.2 mg CO2 kg-1·h-1, and decreased rapidly afterward. Within the entire cold storage period, the respiration rate of the fruits held at 0 °C was considerably lower, indicating that the 0 °C was the most effective on respiration suppression, and effectively delayed the onset of the climacteric peak.

Relative electrolyte leakage and MDA content

As shown in Figure 4, relative electrolyte leakage and MDA content increased gradually with storage time. Marked increase was found when the fruits were kept at 5 °C for 14 days. Significantly (P<0.05) lower level of both values were observed at 0 °C followed by 2 °C. Relative electrolyte leakage and MDA content in 0 °C stored fruit were 53.7% and 46.8% lower, respectively, than those at 5 °C on the 28th day. Therefore, the 0 °C can limit the rise in electrolyte leakage and MDA content effectively, suggesting better membrane integrity. The damage to the cell membrane maybe initiate ethylene production, increased respiration, and disruption of cellular and subcellular structures.

Figure 4: Relative electrolyte leakage (a) and MDA content (b) during 28 days of storage of ‘Okubao’ peach at four different temperatures.

PPO and POD activities

As shown in Figure 5, PPO and POD activities increased gradually during storage. 0 °C significantly (P<0.05) inhibited the activities of both enzymes during the whole storage. The activities of PPO and POD in 0 °C stored fruit were 66.3% and 20.4% lower than those held at 5 °C on the 28th day, respectively. At the end of the storage period, fruits stored at 5 °C underwent vastly increased PPO activity followed by the 8 °C and 2 °C; 0 °C slightly incremented. Since both PPO and POD are associated with woolliness development in peaches, it is possible that 0 °C might have inhibited and delayed woolliness of flesh tissue through the inhibition of PPO and POD activities.

Figure 5: PPO (a) and POD (b) activities during 28 days of storage of ‘Okubao’ peach at four different temperatures.

Conclusion

In this work, when peaches were kept at 0 °C, few chilling injury symptoms appeared and the sensory score significantly exceeded 6. 0 °C swiftly reduced PPO and POD activities and delayed the increase in electrolyte leakage and MDA content, stabilizing cellular integrity. However, serious tissue browning was observed after 21 days of storage at 5 °C, as the CI index of peaches stored at 5 °C increased to 28.8% and they rotted rapidly. By 28 days only fruit at 0 °C improved fruit quality and extended the storage potential through lessening postharvest deterioration and oversoft. Thus it is recommended 0 °C to maintain acceptable visual appearance of peach. Even though the ideal storage temperature for visual appearance of peach fruit is 0 °C, acceptable quality of peaches may be maintained at moderate temperatures such as 2 °C, 5 °C, 8 °C for a short term storage period of 21 days.

Acknowledgements

This research received financial support from the National Key Technology R&D Program of China (2015BAD19B02) and Science and Technology Innovation special construction funded Program of Beijing Academy of Agriculture and Forestry Science (KJCX20170206).

Fa SBN, Gil MI, Cremin P (2001) HPLC-DAD-ESIMS analysis of phenolic compounds in nectarines, peaches, and plums. J Agric Food Chem 49: 4748-4760. [ Ref ]

https://baijiahao.baidu.com/po/feed/ share?wfr=spider&for=pc&context=%7B%22sourceFrom%22% [ Ref ]

Crisosto CH, Valero D, Layne D (2008) Harvesting and postharvest handling of peaches for the fresh market. Peach Botany Production and Uses 49: 575-596. [ Ref ]

Crisosto CH, Mitchell FG, Johnson S (1995) Factors in fresh market stone fruit quality. Postharvest News and Information 6: 17N-21N. [ Ref ]

Mitchell FG, Mayer G, Maxie EC (1974) Cold storage effects on fresh market peaches, nectarines and plums: Estimating freezing points; using low temperatures to delay internal breakdown. California Agriculture 28: 12-14. [ Ref ]

Fernández-Trujillo JP, Martínez JA, Artés F (1998) Effect of cold storage on physiology and quality of Sudanell peach. Journal of Agricultural and Food Chemistry 61: 2655-2660. [ Ref ]

Crisosto CH, Mitchell FG, Ju Z (1999) Susceptibility to Chilling Injury of Peach, Nectarine, and Plum Cultivars Grown in California. Hortscience 34: 1116-1118. [ Ref ]

Mitchell FG, Mayer G, Maxie EC (1974) Cold storage effects on fresh market peaches, nectarines and plums: Estimating freezing points; using low temperatures to delay internal breakdown. California Agriculture 28: 12-14. [ Ref ]

Crisosto CH, Mitchell FG, Ju Z (1999) Susceptibility to Chilling Injury of Peach, Nectarine, and Plum Cultivars Grown in California. Hortscience 34: 1116-1118. [ Ref ]

Zhang B, Xi WP, Wei WW (2011) Changes in aroma-related volatiles and gene expression during low temperature storage and subsequent shelflife of peach fruit. Postharvest Biology and Technology 60: 7-16. [ Ref ]

Crisosto CH, Crisosto GM (2005) Relationship between ripe soluble solids concentration (RSSC) and consumer acceptance of high and low acid melting flesh peach and nectarine (Prunus persica, (L.) Batsch) cultivars. Postharvest Biology and Technology 38: 239-246. [ Ref ]

Crisosto CH, Crisosto GM, Day KR (2008) Market life update for peach, nectarine, and plum cultivars grown in California. Advances in Horticultural Science 22: 201-204. [ Ref ]

Perkins-Veazie P, Roe N, Lasswell J (1999) Temperature manipulation improves postharvest quality of a mid-season peach. Journal of Food Quality 22: 75-84. [ Ref ]

Fernandeztrujilio JP, Martinez JA, Artes F (1998) Modified atmosphere packaging affects the incidence of cold storage disorders and keeps ‘flat’ peach quality. Food Research International 31: 571-579. [ Ref ]

Mitchell FG, Mayer G, Maxie EC (1974) Cold storage effects on fresh market peaches, nectarines and plums: Estimating freezing points; using low temperatures to delay internal breakdown. California Agriculture 28: 12-14. [ Ref ]

Crisosto CH, Mitchell FG, Johnson S (1995) Factors in fresh market stone fruit quality. Postharvest News and Information 6: 17N-21N. [ Ref ]

Fernández-Trujillo JP, Cano A, Artés F (1998) Physiological changes in peaches related to chilling injury and ripening. Postharvest Biology and Technology 13: 109-119. [ Ref ]

Wang YS, Tian SP, Xu Y (2005) Effects of high oxygen concentration on pro- and anti-oxidant enzymes in peach fruits during postharvest periods. Food Chemistry 91: 99-10. [ Ref ]

Cantwell MI, Thangaiah A (2012) Acceptable cooling delays for selected warm season vegetables and melons. Acta Horticulturae 934: 77-84. [ Ref ]

Li J (2000) Molybdenum blue colorimetric method to determine reduced vitamin C. Food Science 8: 42-45. [ Ref ]

Li H, Lin HT, Yuan F, Lin YF, Chen YH (2012) Effects of 1-methylcyclopropene (1-MCP) treatment on postharvest physiology and quality of ‘Younai’ fruits. Chinese Journal of Tropical Crops 33: 279- 285. [ Ref ]

Zhao MX, Yan SJ, Xiao LX (2005) Infrared CO2 analyzer to determine the fruit respiration intensity parameter. Now the instrument 2: 30-32. [ Ref ]

Cao JK, Jiang WB, Zhao YM (2013) Experimental Guidance of Postharvest Physiology and Biochemistry of Fruits and Vegetables, 3rd ed. China Light Industry Press: Beijing, China, pp.101-107. [ Ref ]