Journal Name: Journal of Multidisciplinary Research and Reviews

Article Type: Research

Received date: 30 August, 2019

Accepted date: 02 September, 2019

Published date: 09 September, 2019

Citation: Ji-Hoo K, Hyun-Tae S, Kyoung-Deok K, Myeong-Woo K, Hae-Na Y (2019) The Impact of Initiators on Thermal Expansion Properties of Thermally Expandable Microspheres. J Multidis Res Rev Vol: 1, Issu: 2 (07-12).

Copyright: © 2019 Ji-Hoo K. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Introduction

Thermally expandable microspheres (TEMs) were post-treated with initiators such as potassium persulfate, sodium bisulfite and sodium sulfide to improve the foam expansion ratio and whiteness in the foaming of polyvinyl chloride sol containing thermally expandable microspheres. There was not a significantly difference in the foaming behavior after the post-treatment with potassium persulfate. However, good results were obtained for the foam expansion ratio, whiteness and the yellowing value after the post-treatment with sodium bisulfite. The best result was obtained after the post-treatment with 2% w/w of sodium bisulfite. Therefore, the TEMs post-treated with 2% w/w of sodium bisulfite could be applied in various fields such as coating and wallpaper production, due to their excellent foam expansion and whiteness properties.

Keywords

Potassium persulfate, Sodium bisulfite, Thermally expandable microspheres, Post-treatment.

Introduction

Thermally expandable microspheres (TEMs) were post-treated with initiators such as potassium persulfate, sodium bisulfite and sodium sulfide to improve the foam expansion ratio and whiteness in the foaming of polyvinyl chloride sol containing thermally expandable microspheres. There was not a significantly difference in the foaming behavior after the post-treatment with potassium persulfate. However, good results were obtained for the foam expansion ratio, whiteness and the yellowing value after the post-treatment with sodium bisulfite. The best result was obtained after the post-treatment with 2% w/w of sodium bisulfite. Therefore, the TEMs post-treated with 2% w/w of sodium bisulfite could be applied in various fields such as coating and wallpaper production, due to their excellent foam expansion and whiteness properties.

Keywords

Potassium persulfate, Sodium bisulfite, Thermally expandable microspheres, Post-treatment.

Introduction

A thermally expandable microsphere (TEM) is a polymeric particle with an average particle size of about 5-50 μm. It has a core-shell structure in which liquid hydrocarbons are wrapped in cells of 3-7 μm thickness [1]. Expanding agents contained in these TEMs are usually hydrocarbons, for example, isobutane or isopentane. They have a lower boiling point than the softening temperature of the external polymers of TEMs. They also have a higher vapor pressure. For these reasons, when the TEM is heated, its volume expands 50-100 times as compared with that of before the expansion [2-4]. Because of these properties, TEMs are being applied in various fields. They are generally used to create light weight products with customized material properties such as mass reduction, bulk increase, and improved resilience. Also, the addition of thermally expandable microspheres in printing ink enables the creation of three-dimensional textures for wallpaper, textiles and point-of-print [1].

Nitrile monomers such as acrylonitrile and methacrylonitrile are usually used as core monomers for TEMs because of their excellent gas barrier properties [5]. However, since monomers are not completely converted to polymers in the polymerization reaction, some traces of unreacted monomers remain in polymers [6]. The residual unreacted monomers on the surface of a polymer, after polymerization, may cause deterioration of physical properties of the polymer and change its color due to oxidation. For this reason, the use of TEMs is limited in applications where a high degree of whiteness is required. To mitigate this defect, various methods were proposed to remove the residual monomer in the polymer [7]. In the synthesis of acrylonitrile copolymer, the amount of acrylonitrile was reduced by increasing the polymerization temperature to improve the conversion rate. However, it was difficult to increase the polymerization temperature because of the presence of an expanding agent in TEMs [8]. In addition, the stripping method was used to remove the residual monomer in the polymer, but it was also difficult to apply in TEMs due to their expansion [9]. In the research for the removal of residual acrylonitrile using an adsorbent, the removal of acrylonitrile remaining in water was effective. However, the removal of acrylonitrile that was present on the surface of the polymer was not effective [10].

Some studies on post-polymerization method were carried out to remove residual monomers. However, this method was not successfully conducted for the improvement of whiteness and reduction of the yellowing value while retaining the same or higher foam expansion ratio in polyvinyl chloride. Therefore, this method was difficult to apply in industrial settings such as wallpaper and coating production. This research was conducted to study the effects of the type and content of an initiator on the improvement of whiteness and decrease in the yellowing value in postpolymerization.

Materials and Methods

Synthesis of thermally expandable microspheres

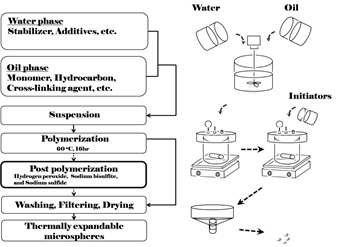

The synthesis of thermally expandable microspheres (TEMs) was conducted as shown in figure 1. First, the aqueous dispersion mixture was prepared by mixing ion-exchanged water (228g), sodium chloride (72g, GR grade, Junsei Chemical Co., Tokyo, Japan), colloidal silica (15g, SS-SOL 30A, POC, Ansan, Korea), polyvinylpyrrolidone (1 g, K-30, Samchun Chemicals Co., Seoul, Korea), and a 10% sodium nitrite aqueous solution (0.7g, GR grade, Samchun Chemicals. Co., Seoul, Korea). The oil phase mixture was prepared by mixing acrylonitrile (30g, EP grade, Junsei Chemical Co., Tokyo, Japan), methyl methacrylate (12g, GR grade, Junsei Chemical Co., Tokyo, Japan), trimethylolpropane trimethacrylate (0.15g, technical grade, Sigma- Aldrich, Inc., St. Louis, MO, USA), iso-pentane (16g) and azobisisobutyronitrile (0.5g, GR grade, Samchun Chemicals Co., Seoul, Korea). Thereafter, the aqueous dispersion mixture and the oil phase mixture were mixed. The resulting suspension was prepared by dispersion using a homogenizer at 1000 rpm for 10 min. After nitrogen substitution of the suspension in a pressure reactor (1L), polymerization was carried out at the polymerization temperature of 60ºC for 16h while stirring at 400 rpm, at an initial reaction pressure of 0.2 MPa. TEMs were obtained by filtering and drying polymerized products.

Figure 1: Preparation process of thermally expandable microspheres.

The thermal expansion properties of the obtained TEMs were measured using a thermal expansion analyzer (TMA Q400, TA Instruments, New Castle, DE, USA) at the rate of 10ºC/min from 50 to 250ºC. The measured properties were the temperature at which the expansion started (Tstart), the temperature at which the maximum expansion was reached (Tmax), and the level at which the maximum expansion was reached (Dmax). The surface of the synthesized microspheres was photographed using a scanning electron microscope (SEM AIS2300C, Seron Technologies Co., Uiwang, Korea) and an optical microscope (E200LED, Nikon Instruments Inc., Melville, NY, USA). The average particle size (D50) of the synthesized microspheres was measured using a particle size analyzer (Mastersizer 2000S, Malvern Instruments Ltd., England).

Post-polymerization

After thermally expanding microspheres were polymerized, the initiators such as potassium persulfate, sodium bisulfide and sodium sulfite were added. These reacted at 70ºC for 5h in a sealed vessel. After the reaction, the product was filtered and dried to obtain post-treated thermally expandable microspheres.

PVC Sol foaming test

Polyvinyl chloride (PVC) sol for a foaming test was prepared by mixing PVC (100g, LP170, LG Chem., Seoul, Korea), dioctyl phthalate (60g, Sigma-Aldrich), heavy calcium carbonate (40g, Sigma-Aldrich) and BZ810P-5 (1g, Songwon, Seoul, Korea). Dried TEMs (1g) were added into the resulting PVC sol. Then, the mixture was blended. The resulting mixture was, then, coated onto wallpaper to a thickness of 200 μm. The coated specimen was gelled at 110ºC. The thickness of the gelled specimen was measured using a thickness gauge. After the gelled specimen was foamed at 200ºC, the expansion ratio was calculated by dividing the thickness before and after the expansion.

Discoloration measurement of the test specimen by a color difference meter

The whiteness index (WI) and yellowing value (b) were measured using a colorimeter (Konika Minolta, CM-2500d, Konika Minolta Co., Tokyo, Japan) to assess the brightness, color and saturation of the PVC sol foam specimen.

Results and Discussion

Shape of the synthesized thermally expandable microspheres

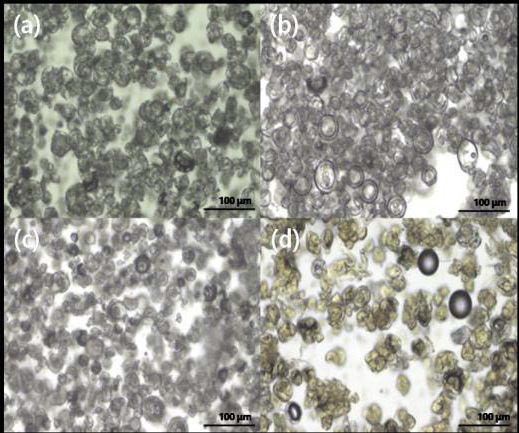

The microscopic image of microspheres prior to treatment with an initiator is shown in figure 2 (a). The microspheres post-treated with 1% w/w of potassium persulfate, sodium bisulfite and sodium sulfide initiator are shown in figure 2 (b), (c) and (d), respectively. Chen et al. reported that 2,2’-azobisisobutyronitrile (AIBN) and benzoyl peroxide (BPO) used as initiators, generated more radicals and initiated polymerization, resulting in not-aslong polymer chains (Mn = 4500) [11-13]. Gonçalves et al. (2008) reported that the nucleation rate of PMMA domains increased, with increasing radical formation due to initiator decomposition [14].

Figure 2: Microscopic images of microcapsules treated with: (a) none, (b) potassium persulfate, (c) sodium bisulfite, and (d) sodium sulfide.

The microscopic images in figure 2 (b) and (c) are similar to those in figure 2 (a). Various shapes and surface of particles were shown in expandable microspheres using n-pentane [12]. However, after the TEMs were post-treated, it was confirmed that the particles clustered together and the spaces between the TEMs became very wide, as shown in figure 2 (d). This result might suggest that the internal hydrocarbons were released due to the external collapse of TEMs during their post-treatment with sodium sulfide, which seems to be similar with the post-treatment with other initiators.

Thermal expansion property of synthesized thermally expandable microspheres

Table 1 shows the physical properties of TEMs that were post-treated with initiators. With the use of initiators, Tstart of synthesized microspheres did not differ, except when they were post-treated with sodium sulfide, which brought a small change in volume. Tmax of synthesized microspheres post-treated with sodium bisulfite was the highest. Dmax of synthesized microspheres post-treated with sodium sulfide was significantly lower than Dmax of synthesized microspheres post-treated with other initiators. This result might suggest that microspheres did not foam properly because hydrocarbons in TEMs leaked to the collapsed outer wall during the post-treatment.

Table 1: Thermal expansion properties of synthesized microspheres with initiators.

| Properties | None | Potassium persulfate | Sodium bisulfite | Sodium sulfide |

|---|---|---|---|---|

| Tstart (ºC) | 144.9 | 144.3 | 144.5 | 149.3 |

| Tmax (ºC) | 161.1 | 161.5 | 164.2 | 157.3 |

| Dmax (μm) | 2588 | 2329 | 2859 | 158 |

| Particle size (μm) | 24.3 | 27.6 | 21.8 | 22.3 |

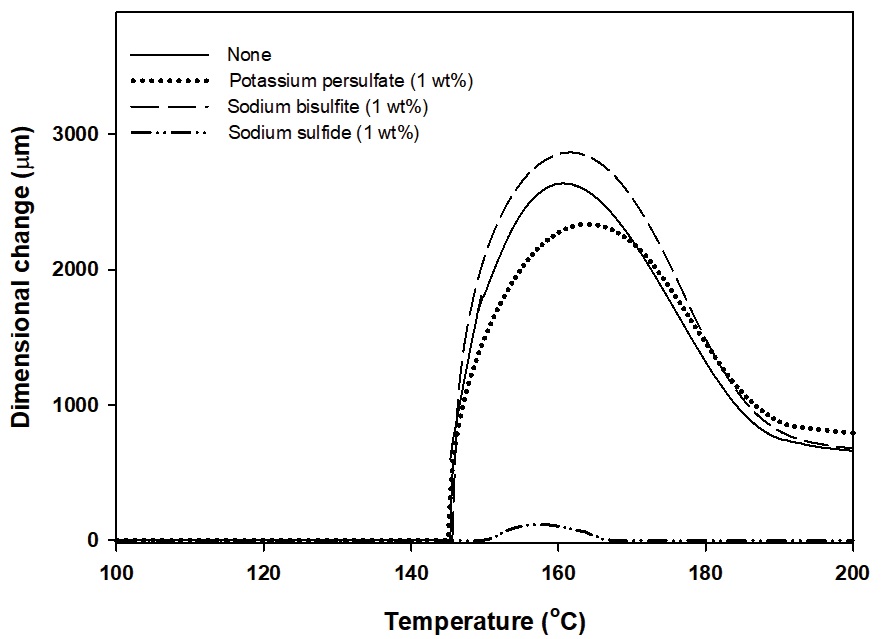

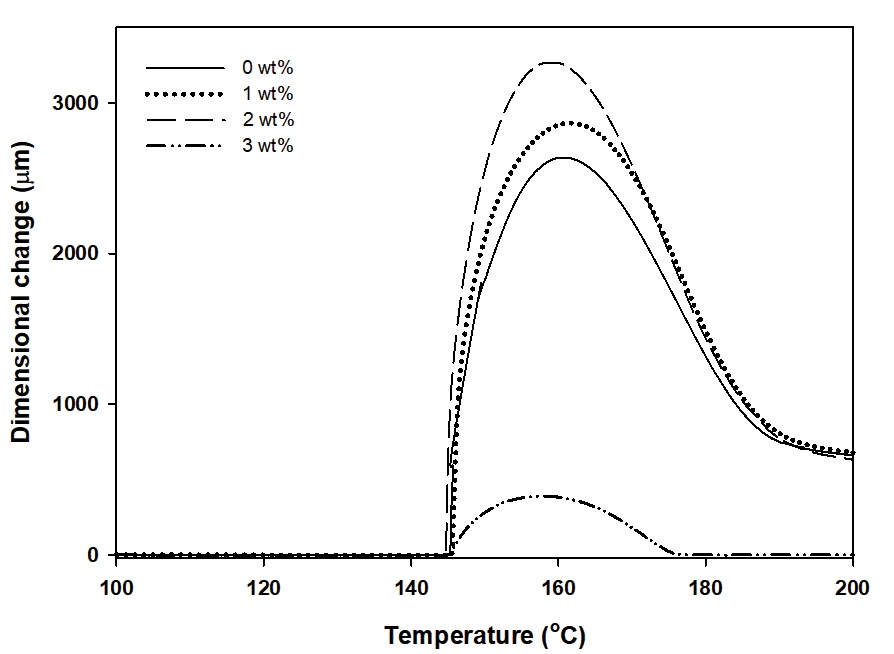

Figure 3 shows the TMA curve of TEMs post-treated with initiators. Potassium persulfate caused a small change in the volume of the synthesized microspheres. Sodium bisulfite led to a slight increase in the volume of the synthesized microspheres when compared to their volume before the post-treatment. When sodium sulfate was used, the increase in the volume was relatively low. This seems to be due to the low gas barrier property of the TEMs’ outer polymer in the post-treatment process. It was thought that the leakage of internal hydrocarbon due to the low gas barrier did not change the volume of the synthesized microspheres. In the case of post-treatment with sodium bisulfate, the residual monomer was effectively removed. When the microspheres post-treated with sodium bisulfate were compared to those post-treated with other initiators, the volumetric change appeared to be the highest since the content of the TEMs per unit mass increased.

Figure 3: TMA for the TEMs subjected to different post-treatments.

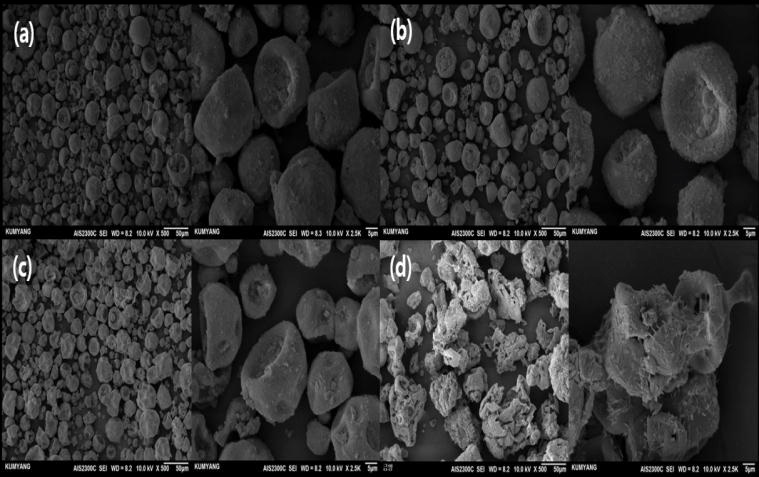

Figure 4 shows the photograph of the synthesized TEMs using SEM. It can be seen that the synthesized TEMs have a spherical shape which is somewhat distorted in shape. Vamvounis et al. reported that SEM images of the functionalized TEMs by reacting with the thiophene acid chloride and grafting with poly (3-n-dodecylthiophene) show the consistency of their shapes and flaky surfaces. It was reported that the capsule shape is deformed gradually into a distorted microsphere by a crosslink agent during synthesis [13]. The capsules synthesized in this study were also considered to have this shape due to the addition of a crosslink agent. In figure 4 (a), (b) and (c), the TEMs before the post-treatment are not significantly different from those after the post-treatment with potassium persulfate and sodium bisulfate. The shape and distribution differences of the TEMs post-treated with AIBN and BPO as initiators, were considered to be due to the different thermal decomposition temperatures of AIBN and BPO [11]. However, when sodium sulfide was used in the post-treatment, it almost did not foam, as shown in figure 4 (d). It is possible that this result occurred because the outer shell of the TEMs collapsed, and the hydrocarbon that acted as an internal expanding agent leaked.

Figure 4: SEM Images (×500, ×2500) of thermally expandable microspheres: (a) none, (b) potassium persulfate, (c) sodium bisulfite, and (d) sodium sulfide.

Expansion test of PVC sol

PVC sol is the medium used most often in the production of wallpaper containing TEMs. The PVC sol containing the TEMs post-treated with 4 types of initiators was foamed to test its possible applications. Table 2 shows the results of the foam expansion ratio and colorimetric analysis obtained from PVC sol with these TEMs. When untreated TEMs were used in PVC sol, the foam expansion ratio of the PVC sol was 230 times higher. The foam expansion ratio of the PVC sol increased slightly after the post-treatment with potassium persulfate and sodium bisulfite. On the other hand, PVC sol containing the TEMs post-treated with sodium sulfide showed almost no foaming. The yellowing value (b) reduced consequently when sodium bisulfite, potassium persulfate, no initiator and sodium sulfide were used. The WI increased consequently when sodium bisulfite, no initiator, potassium persulfate and sodium sulfide were used. Based on these results, it was confirmed that the TEMs post-treated with sodium bisulfite improved the foam expansion property and the whiteness of PVC sol but decreased its yellowing value.

Table 2: Results of PVC sol test.

| Properties | None | Potassium persulfate |

Sodium bisulfite | Sodium sulfide |

|---|---|---|---|---|

| Expansion ratio (%) | 230 | 233 | 242 | 140 |

| Whiteness index (WI) | 81.6 | 82.3 | 83.7 | 78.5 |

| Yellowing (b) | 13.9 | 12.9 | 11.4 | 17.9 |

Effect of sodium bisulfite content on expansion properties

The effect of sodium bisulfite content on the foaming expansion ratio, whiteness and the yellowing value of PVC sol containing TEMs was investigated. This was because sodium bisulfite improved the foaming expansion ratio, WI and decreased the yellowing value of PVC sol. The TMA curves of the TEMs post-treated with different amounts of sodium bisulfite are shown in figure 5. The expansion properties and particle sizes of the TEMs are listed in table 3 according to the sodium bisulfite content. As shown in table 3, the highest change in volume was observed when 2% w/w of sodium bisulfite was added. In addition, the smallest particle size was obtained when the TEMs were post-treated with 2% w/w of sodium bisulfite. Bu et al. reported that the greatest expansion rate occurred in the capsules containing 0,05 mol% 1,4-butanediol dimethacrylate (BDDMA), ranging from 0 to 0.08 mol% [4]. This was considered to be due to the most active vaporization of the liquid hydrocarbons present in the core of the capsules, containing 0.05 mol% [4].

Table 3: Effects of sodium bisulfite content on expandable properties and particle sizes.

| Content (wt%) | 0 | 1 | 2 | 3 |

|---|---|---|---|---|

| Tstart (ºC) | 144.9 | 144.5 | 144.1 | 143.1 |

| Tmax (ºC) | 161.1 | 164.2 | 163.7 | 159.5 |

| Dmax (μm) | 2588 | 2859 | 3250 | 172 |

| Particle size (μm) | 24.3 | 21.8 | 18.3 | 20.7 |

Figure 5: Effects of sodium bisulfite content on expandable properties.

Conclusion

After polymerization, in order to improve the foam expansion ratio and whiteness of the foam medium using polyvinyl chloride, thermally expandable microspheres (TEMs) were post-treated with initiators such as potassium persulfate, sodium bisulfite and sodium sulfide. There was no significant difference in the foaming behavior as a result of the post-treatment with potassium persulfate and sodium bisulfite. The post-treatment with sodium sulfide did not produce foam. The whiteness index (WI) and yellowing value (b) of the TEMs post-treated with sodium bisulfite were better than those of the TEMs post-treated with other initiators. When sodium bisulfite was used as an initiator, PVC sol containing TEMs showed the most excellent foam expansion ratio, the highest level of whiteness, and the lowest yellowing value. The change in volume was the highest for the specimen with added 2% w/w of sodium bisulfite. Therefore, the TEMs post-treated with 2% w/w of sodium bisulfite could be applied in various fields such as in coating and wallpaper production, because of their excellent foam expansion and whiteness properties.

Acknowledgement

This research was conducted with the support of the World Class 300 Project R&D Support Project (S2433278) in Korean Small and Medium Business Administration.

There are no references